Markforged 3D Printers & 3D Printing Capabilities

Markforged changes what you know about a 3D printer and metal printing. Markforged 3D printers transcend the realm of 3D printer prototyping and trinkets. Find the right Markforged 3D printing solution for your needs.

Five Applications of Metal 3D Printing

Markforged provides unique 3D Printers and technologies that print carbon fiber parts reinforced for metal-strength. This Markforged technology breaks down the barriers between idea and reality. See Markforged's Top Five Applications of Metal 3D printing white paper. Learn how Markforged provides so many advantages over conventional fabrication methods.

Markforged Metal X 3D Printer

Markforged’s Metal X 3D Printer Makes Metal Printing Easy and Affordable.

This Markforged 3D Printer greatly accelerates innovation. The Metal X 3D Printer delivers metal parts overnight using a new technology at a fraction of the cost. Markforged leaves 20th century manufacturing in the dust. With Markforged 3D Printers’ technology you can create anything from industrial replacement parts to injection molds to working prototypes.

Markforged’s Metal X 3D Printer Features

The Markforged’s Metal X 3D Printer is the most advanced metal 3D Printer. Discover the Markforged 3D Printer’s capabilities:

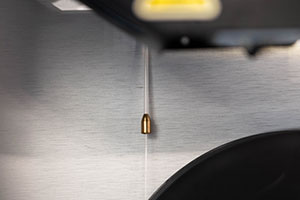

ATOMIC DIFFUSION ADDITIVE MANUFACTURING (ADAM)

A fantastic Markforged 3D Printer feature that involves using a bound metal powder rod embedded inside a plastic filament for an innovative production process.

MARKFORGED’S EIGER SOFTWARE

Eiger is the world’s most advanced cloud-based, 3D printing software that allows for real-time fleet management.

MARKFORGED MATERIAL TRACKING

Automatic material usage tracking and out-of-material detection make the Metal X 3D Printer systems the simplest way to reduce waste.

Markforged's Metal X 3D Printer Post-Processing Equipment

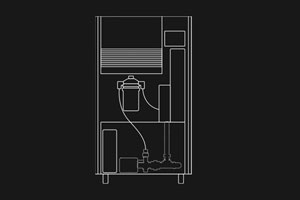

MARKFORGED SINTER - 1

A high performing, high value, medium-sized furnace, the Markforged Sinter-1 effortlessly converts brown (washed) parts into their near fully dense final metallic form. At 4,760 cubic cm of working volume, the Sinter-1 is ideal for small batch production.

MARKFORGED SINTER - 2

A large furnace with a huge active hot-zone (19,644 cubic cm, 1,199 cubic in), the Markforged Sinter-2 is ideal for significant parts or batch production. Sinter a full range of commercial-grade metals from their washed state into dense metal parts.

MARKFORGED WASH - 1

This washing station immerses the green part in a specialized fluid which removes the primary binding material, leaving the part semi-porous so the remaining binder can easily burn off during sintering. This debinding step purifies the final metal part and helps keep your sintering furnace clean.

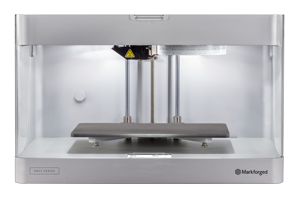

Markforged's Industrial Series 3D Printers

A Markforged 3D Printer That Provides the Strength You Need for Tooling and Functional Parts

The Markforged Industrial Series 3D Printers are designed for accuracy and built to survive the production floor environment, saving you time and money. These Markforged 3D Printers give you the flexibility to print up to 50x faster and 20x cheaper than conventional manufacturing methods, including chopped carbon to continuous fiberglass and ultimately all continuous fiber printing.

Markforged's Industrial Series 3D Printer Features

The Markforged Industrial series is reliable, robust and repeatable. These Markforged 3D Printers enable users to produce products faster and cheaper than traditional machining. Check out some of the amazing Markforged 3D Printers' features below:

LASER PRECISION

Markforged ensures your prints come out exactly how you want them with a built-in laser micrometer that automatically scans the print bed with 1µm accuracy to generate a contour map of its surface.

MARKFORGED 3D PRINTER USABILITY

Cloud-connected software and a 4.3” touchscreen comes standard with every Markforged printer, washer, and furnace

SUPERIOR MARKFORGED 3D PRINTER BUILD QUALITY

Markforged sets the standard in 3D Printer build quality and industrial design with a 4th generation, all-aluminum unibody, and print system.

Markforged's Industrial Series 3D Printers

The Markforged X3 3D Printer produces parts that are 20% stronger and 40% stiffer than ABS. This cost-effective Markforged 3D printer delivers plastic parts made from chopped carbon filament reinforcement to produce parts that are resilient to impact and a wide variety of manufacturing chemicals.

The Markforged FX20 3D Printer is the biggest, fastest, and most sophisticated 3D printer the company has ever built. The new turbo mode allows the FX20 to build parts faster than any other Markforged machine. This easy-to-use printer works with Onyx, Carbon Fiber, ULTEM™ 9085 Filament, and now the newest material Vega™. With new innovations like a build chamber 5x the size of any other Markforged machine, the FX20 is the definition of production-ready performance.

The Markforged FX10 is even faster and easier to use while delivering strong, accurate parts on every print. Built on the same principles of the Markforged X7, this next-generation industrial composite 3D printer boasts several capabilities that set it apart from its predecessors. With a print chamber twice the size of the X7, the FX10 provides a more spacious printing environment while also ensuring rapid and efficient printing processes. The FX10 is designed for user convenience with automated workflows and features a printhead-mounted vision system equipped with capture detailed images of calibration parts, allowing the printer to assess and optimize its performance.

The Markforged FX20 combines great dimensions and processing capacity to facilitate the creation of larger builds at immaculate speeds. Tailored for a wide range of applications, the FX20 is built to create strong, high temp parts. An intricately crafted, sensor-guided manufacturing 3D printer that achieves groundbreaking reliability and performance with a simple user experience. It's the only 3D printer compatible with Vega™, Markforged’s first engineered high temperature plastic. The FX20 features turbo mode, continuous fiber reinforcement, and a build chamber 5x the size of any other Markforged machine. Compatible with Onyx™, Vega™, ULTEM™ 9085 Filament, and Onyx FR™.

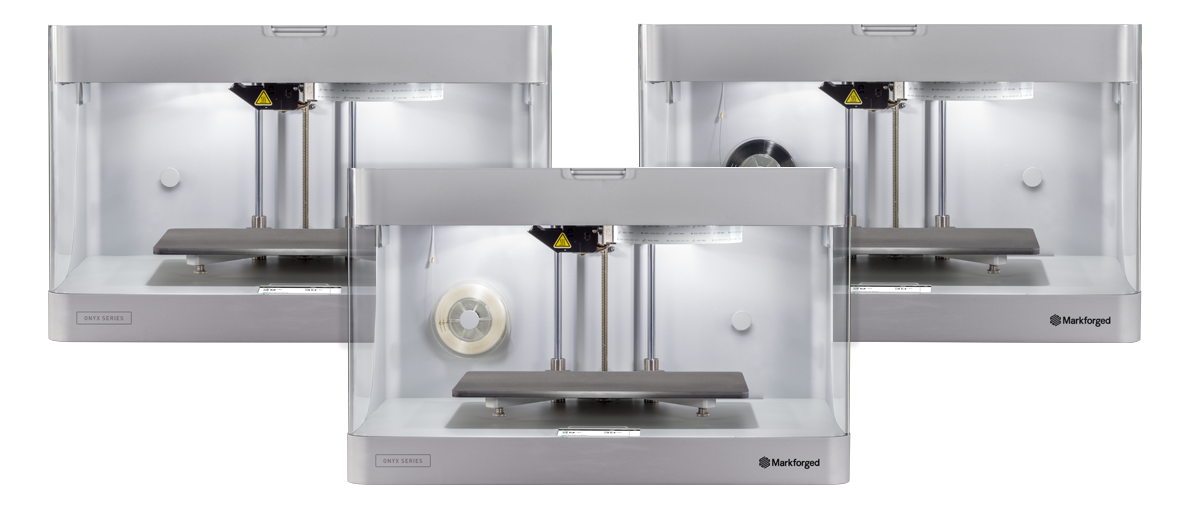

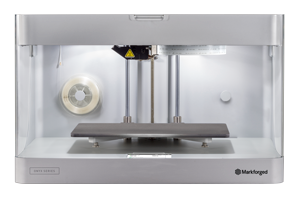

Markforged’s Desktop Series 3D Printers

A Markforged 3D Printer That Combines Industrial Quality and Affordability That Fits on Your Desktop

The Markforged Mark Two 3D Printer is built on the DNA of the Markforged Industrial Series 3D Printers. This Markforged 3D Printer is designed from the ground up for quality and reliability. It combines Markforged's unique continuous carbon fiber reinforcement with workhorse reliability for the strongest, most versatile parts in our portfolio. Markforged Onyx printers' base material is a blend of nylon and chopped carbon for stronger and stiffer parts than plastics other printers use—and that stand up to corrosive chemicals common in manufacturing. Get started with the economical Markforged Onyx One or step up to the Markforged Onyx Pro to boost part strength 10x by embedding continuous fiberglass.

Markforged Desktop 3D Printer Series Features

Discover these Markforged 3D Printers’ incredible features at your fingertips and streamline your workflow.

MARKFORGED 3D PRINTER TOUCH SCREEN

Connect to wifi, start prints, and manage your Markforged printer with ease via the built-in touchscreen.

CONTINUOUS FILAMENT FABRICATION

Unique fabrication process enables you to print parts that are an order of magnitude stiffer and stronger than typical 3D printed objects.

HUMIDITY CONTROL

Fully enclosed build chamber, ultra-quiet motion system, and humidity controlled material storage.

Markforged Desktop Series 3D Printers

MARKFORGED ONYX ONE 3D PRINTER

The economic Markforged Onyx One 3D Printer delivers parts with a beautiful surface finish and industrial quality. This Markforged 3D printer creates stiff and dimensionally stable engineering grade parts with twice the strength of other 3D plastic printers.

MARKFORGED ONYX PRO 3D PRINTER

The Markforged Onyx Pro 3D Printer nails the sweet spot of power and affordability. This Markforged 3D printer prints composite parts that are 10 times the strength of plastic by reinforcing chopped-carbon nylon with continuous strands of fiberglass.

MARKFORGED MARK TWO 3D PRINTER

The Markforged Mark Two 3D Printer combines Markforged's unique continuous carbon fiber reinforcement with workhorse reliability for the most durable, versatile parts. This Markforged 3D printer gives you the power to achieve high-performance parts straight off the print bed.

Markforged Digital Source™

Digital Source is a digital warehouse of OEM certified parts that can securely be licensed for 3D printing. Manufacturers can save both time and money by avoiding the need to handle physical inventory, and this, in turn, allows customers to receive parts faster.

How it Works:

- Everything takes place in Eiger which is the 3D printing software that powers Markforged

- Upload a part, define print parameters, and set the price

- Digital Source locks the manufacturer’s original setting so the part will be printed as intended

Benefits:

- Approved customers can shop digital catalogs and print parts

- The security of Digital Source prevents others from downloading, modifying, or reverse engineering the design

- OEMs’ get paid for their designs while also providing customers the flexibility to print parts when are where they are needed

- Digital Source is an easy way to license OEM certified parts with the benefits of lowering inventory costs

- Simplifies operations and increases customer satisfaction

Markforged Digital Forge Subscriptions

Elevate your organization’s 3D printing capabilities with Digital Forge subscriptions, offering a comprehensive solution for robust and functional part production. Benefit from on-demand training to enhance proficiency, extensive support for maximum productivity, and cost efficiency through a unified subscription plan for your entire team. The heart of Digital Forge is Eiger, Markforged’s cloud-based slicing system. This empowers you with advanced software features and user-friendly tools for simulation, inspection, and management. Ensure continuous peak performance with reactive support, wear and tear part replacement, accidental damage coverage, and more. Explore the various subscription tiers to discover the perfect fit for your organization’s needs. Streamline your 3D printing process with confidence and efficiency using Digital Forge.

Markforged 3D Printer Materials

Markforged 3D Printer Composites

Markforged offers four reinforcement fibers: carbon fiber, fiberglass, HSHT fiberglass, and Kevlar. Composites are parts made up of more than one material that, when combined, have synergistic properties different from the original materials.

CARBON FIBER FILAMENT

The strongest and stiffest fiber with the highest strength-to-weight ratio. Carbon fiber filament can replace aluminum at half the weight. Utilize this material when you want exceptional stiffness and minimal deflection.

MARKFORGED ONYX FR

Achieves V-0 rating on the UL94 flammability test while possessing similar mechanical properties to Onyx. It’s best for 3D Printer applications in which flame retardancy, lightweight, and strength are required.

MARKFORGED HSHT FIBERGLASS FILAMENT

With the highest impact resistance and a flexural strength only second to carbon fiber, Markforged HSHT Fiberglass is ideal for 3D Printer applications requiring high heat resistance such as welding fixtures or thermoset molds.

MARKFORGED ONYX FILAMENT

Best in class for surface finish, chemical resistivity, and heat tolerance. Print Onyx alone or reinforce it with one of our continuous fibers to give strength comparable to aluminum.

FIBERGLASS FILAMENT

Fiberglass is the perfect entry-level fiber for a Markforged 3D printer. It's low cost and 26x more rigid than nylon. Print parts that are an order of magnitude stiffer than typical 3D printed objects and produce functional prototypes, fixtures, jigs, and much more.

KEVLAR FILAMENT

As stiff as fiberglass and much more malleable, Kevlar possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. An excellent option for a wide range of applications such as end effectors, cradles, soft jaws, and end-use parts.

Markforged 3D Printer Metals

3D print easily and affordably with the superior properties of Markforged 3D Printers and advanced metals.

H13 TOOL STEEL

This steel works excellently in high temperature and can withstand extreme cooling. H13 tool steel also offers superior abrasion resistance and machinability that makes it ideal for molds and wear resistant pieces.

A2 TOOL STEEL

Regarded as a "universal" cold work steel that offers a combination of excellent wear resistance (between O1 and D2) and toughness.

COPPER

Copper is a soft, malleable metal valued for its electrical and thermal conductivity. Ideally used for projects that require high conductivity, copper is the perfect material for heat sinks and heat exchangers, power distribution components, manufacturing equipment, and much more.

17-4 PH STAINLESS STEEL

A high-strength, high-hardness metal with excellent corrosion resistance, this versatile steel excels in manufacturing, aerospace, petroleum, and medical industries. If heat treated, 17-4 PH Stainless Steel has an ultimate tensile strength of 1250 MPa and a Rockwell Hardness of 36 HRC.

INCONEL 625

Not only is this metal easy to print, but it is also extremely resistant to corrosion and is durable at high temperatures. Therefore, Inconel 625 is perfect for prototypes and end-use parts that are designed to sustain harsher environments.