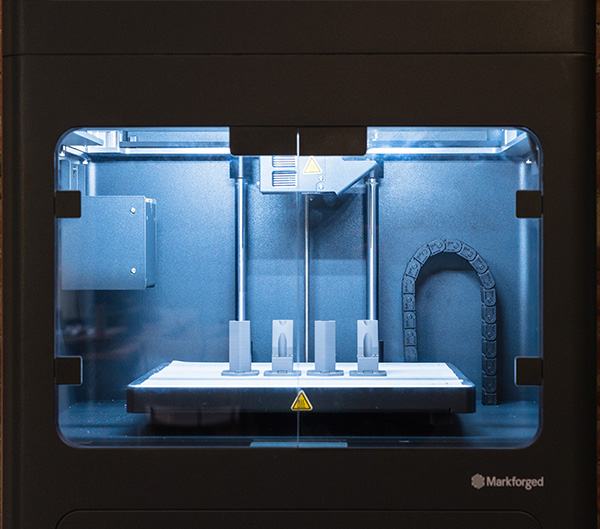

Markforged Metal X 3D Printer

The Metal X 3D Printer Forges Parts Quickly and Affordably

Meet the Metal X 3D Printer by Markforged. The Markforged Metal X 3D Printer uses 4th generation Markforged composite 3D printing technology. The Metal X eliminates safety risks associated with traditional metal 3D printing methods by printing metal powder bound in a plastic matrix.

How the Markforged Metal X 3D Printer Works

The Markforged Metal X 3D printer dominates the industry. The Markforged Metal X 3D printer is up to 10 times less expensive than alternative metal 3D printers and up to 100 times less than traditional fabrication technologies like machining or casting.

The Markforged Metal X 3D Printer is a brand new metal 3D Printer that can produce fully-functional metal parts. The Markforged Metal X eliminates the safety risks associated with traditional metal additive manufacturing while enabling new features like closed-cell infill for reduced part weight and cost.

STEP 1

First, CAD your product, upload the STL, and choose from a wide range of metals.

STEP 2

Next, metal powder bound in plastic prints layer by layer into the shape of your design.

STEP 3

Then, the plastic dissolves, and the metal sinters in a furnace.

STEP 4

Now, the robust, functional, metal parts are ready for use.

Need Help With a Markforged Metal X 3D Printer?

Saratech's 3D printing team is committed to your success. We provide everything you need to get your Markforged Metal X 3D printer system up and running, while assisting you in being more productive!

We can also advise you on 3D printing orientation, fiber routing, and guide you in creating and making components stronger or faster.

Connect With a Saratech Expert Today to Get Started.

Markforged Metal X 3D Printer Capabilities

The Metal X 3D printer offers an end-to-end manufacturing system that makes producing metal parts unprecedentedly simple. Markforged and the Metal X 3D printer offers s cloud-based management software that enables you to 3D print plastic, metal, and composite parts straight from your browser. The Markforged Metal X 3D printer provides a built-in touchscreen interface allows for each user's experience to be smooth and hassle-free. The Markforged Metal X makes reducing waste easy as well with automatic material usage tracking.

Metal X’s 3D Printer Unique Capabilities

- Eiger - the world's most advanced 3D printing software

- Atomic diffusion additive manufacturing technology for an innovative way to produce metal parts

- Fully enclosed build chamber, ultra-quiet motion system, and an environmentally enclosed material storage

Markforged Metal X 3D Printer Post-Processing Equipment

MARKFORGED SINTER-1 AND THE METAL X 3D PRINTER

The Sinter-1 is a high-performing, medium-sized furnace that is fast and affordable. Place multiple parts on a ceramic bed and slide them into a uniform hot zone with ease. Allow the furnace to sinter, and in just hours you have perfectly sintered parts. The Sinter-1 connects to Markforged software to monitor the sintering run and send you an email when the part is complete.

Furnace Dimensions: 1,067mm x 483mm x 406mm

Furnace Volume: 4,760 cubic cm

Peak Temperature: 1,300° C

MARKFORGED SINTER-2 AND THE METAL X 3D PRINTER

For printing large-parts and batch production with the Metal X 3D P rinter, the Sinter-2 has an expansive hot zone that can get the job done. During the sintering process, the part is run through a series of ramp and hold temperatures. The metal powders sinter together fused up to 99 percent dense metal - leaving you with a part with exceptional strength and stiffness. Additionally, you'll be able to login to the connected software at any time to monitor the sintering process.

Furnace Dimensions: 1,200mm x 700mm x 1,500mm

Furnace Volume: 19,644 cubic cm

Peak Temperature: 1,300° C

MARKFORGED WASH-1 AND THE METAL X 3D PRINTER

Clean your freshly printed part in just hours! The Wash-1 removes about half of the binding material from an object by immersing it in a specialized fluid. The washing station connects to Markforged software, making the process as simple as running a dishwasher. The software lets you know precisely how long the wash will take and will alert you with an email when the part is ready for sintering.

External Dimensions: 609mm x 685mm x 1,067mm

Washing Volume: 18,356 cubic cm