Build Custom Solutions for Additive Manufacturing

NX offers users the tools and resources to create flawless part designs for 3D printing. Leveraging 3D printing technology leads to market gains, lower costs, and top tier product quality. NX also helps users get it “just right” the first time, leading to time and material saving during manufacturing.

Benefits

NX provides all the necessary capabilities for additive manufacturing, from design to print to post-print validation. This is beneficial because users not only can prototype but also manufacture groundbreaking products in a new and improved way. NX allows users to deliver:

- Realistic Modeling and Concept Design

- Post Processing and Order Management

- Quality and Analytics

Capabilities

Additive Manufacturing Design

Additive Manufacturing Design

Additive manufacturing provides the ability to manufacture highly complex designs with features like optimized surfaces and lattice structures. NX allows users to design and print complex geometries at scale.

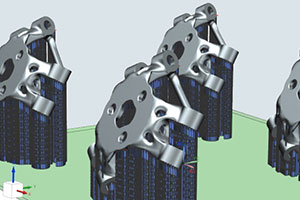

Build Preparation

Build Preparation

Quality, efficient output from the AM process requires the proper initial setup. The integrated build preparation tools in NX assist with placing, orienting, and supporting parts in the build tray is the most efficient manner possible to surpass expectations. With support structures and build tray part placement/nesting users have a massive advantage.

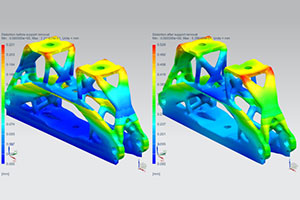

Build Simulation

Build Simulation

Simulation of the build process can help you generate quality 3D prints at scale. From build orientation optimization to meso-scale deposition path optimization users can identify areas of very local overheating that can result in deformations or problems with consistent material deposition.

Quality and Analytics

Quality and Analytics

NX offers the ability to closely monitor the additive manufacturing process, analyze the data and act upon to improve the parts and process.

Case Studies

Have Questions?

We Can Help! Contact Us Below: