Solid Edge

With Solid Edge, you can streamline access to the latest manufacturing methods, ensuring your 3D print is right the first time.

Here are some frequently asked questions regarding Solid Edge. If you still need help regarding your engineering software feel free to contact us for further assistance.

NX CAD

NX CAD empowers designers to achieve faster results using more virtual product models and fewer, costly, physical prototypes.

Here are some frequently asked questions regarding NX CAD. If you still need help regarding your engineering software feel free to contact us for further assistance.

Token, or Value Based Licensing allows customers to use a broad set of different products through a system of tokens that are compatible with, and extend, existing licensing options. The tokens are enabled on top of prerequisite base seat license(s). They are available on Subscription basis.

Customers buy a fixed number of tokens allowing them to use whatever token-enabled product as long as they don’t exceed the combined token count they have purchased. When the customer exits NX, the token amount is released again, so that people can start-up other software options.

“Tokens” are available in sets that are referred to as “Value-Packs”. Token licensing is available in NX 12.0.2 MP14 and for the Continuous Release series NX 1872 and onward. Note, customers on NX 12 will have to download and install the MP14 service pack. A customer must have purchased pre-requisite base seat license(s) which include the floating NX Mach 1 license and above or the Automotive bundles. The following are NOT valid base seats for tokens:

- Mach Designer

- Mach Advantage

- Mach 1 Node Locked

- Gateway or UG based bundles

Users purchase a package of tokens to include in the token pool, these are sold in value packs of 50 and 100. The first token pack must be 100 after which tokens can be purchased in quantities of 50 or 100.

Tokens are an extremely flexible way to invest in NX. They dramatically lower the costs and risks associated with new projects (where customers are starting to use NX but do not yet know the quantity of and the add-on tools they really need). While most companies will see value in this approach, it may be easiest to describe the value to smaller customers who use many types of design tools and companies where multiple teams need different tools at different times.

The NX Design Value Packs are only available as subscription, so all the benefits of subscription licensing apply. Additional benefits include:

- Extreme simplicity because new customers only need to buy tokens to cover an overall capacity requirement. This is made up of a number of desktop licenses and a quantity of tokens and avoids customers having to make decisions on each individual product option. Guidance for Sales to help configure token installations is provided at the end of this document.

- Increased business flexibility because customers can adapt to different development requirements quickly without having to re-invest.

- Increased cost savings for customers who will run a wide variety of applications on an occasional basis. These customers don’t have to consider peak requirements for individual products but can rather model requirements on overall capacity requirements. Traditional licensing often requires customers to overinvest in individual product licenses, even if 90% of the time there is no real need for the maximum number of licenses.

- Reductions in internal purchasing paperwork because customers invest in tokens which allow them to use product you use daily and products you only use occasionally (or don’t even know you need yet).

- Additional risk reduction:

- Reduces the risk of over-investing in a certain product options while ensuring customers have the broad range of products at their disposal. Doing this in a subscription context allows them to flexibly adjust their token count on a yearly basis.

- A product option might not have been selected during the procurement process, while afterwards that software option might become critical for a specific (urgent) project.

- Time savings (vs acquisition of technology).

- Many new software options will be supported by the token system.

- Maybe the customer does not really know what they will need so wants a way to be able to use many options and confirm they add value before deciding how to buy them.

NOTE: While the plan is to deliver new products with tokens customers. It is important from a rev rec viewpoint to avoid any commitments that new capabilities will automatically become available in the token pool.

The tokens are packaged into value packs:

- NX35100 – NX Value Based Licensing 100 pack

- NX35050 – NX Value Based licensing 50 pack

No, there are over 50 products in the token pool, but there are some exceptions. The token pool does not include:

- Products with royalty. This ensures we do not violate any partner agreements.

- Programming authoring tools (NX Open Authoring). This prevents the situation where authoring tools are not available to the people designated to use them at our customers because the token pool is exhausted.

Tokens that have been purchased by a customer become part of a token license pool. Each application in the token pool consumes a defined number of tokens when in use. Total number of applications, and which specific applications, that can be checked out on top of the Base Application is limited by the number of tokens that the user has available. When the customer exits NX, the token amount is released again, so that people can start-up other software options.

Token licensing can be combined and mixed with the traditional feature-based licensing schemes which also continue to exist. As described above third-party products will not be available under the token licensing scheme. A customer must have purchased pre-requisite base seat license(s) on top of which the tokens can be enabled. Token licensing does NOT require Teamcenter or any other application beyond the basic license referred to here in order to function. If this is used with any other licensing, then the licensing system will use “non-token” licenses first before using tokens. The strategy is always to maintain as many tokens as possible in the available pool. Based on the number of tokens purchased, people will be able to activate a number of software options. The system will allow any token enabled license to be used if there are sufficient tokens available. When the user exits the application, the tokens are returned to the pool.

This approach has strong benefits for both small deployments requiring broad set of applications or products and for large deployments with many applications / products. The majority of our customers probably fall into the middle where traditional licensing is felt to be best solution.

If a customer has need for a single application like MCD or Mold then it is most likely the most cost effective approach is to sell the specific products.

Looking at each as examples:

- NX11113 Mechatronics Concept Designer – $35,200 plus $7745 ME&S

Using tokens

- NX11110 Mach 1 Product Design – $16,129 plus $3535 ME&S

- NX35100 NX Value Based Licensing 100 pack – $16,308 p.a.

While year 1 is slightly lower cost, ($43K to $36K) the customer breakeven is approximately 17 months into the contract.

- NX13200 MoldWizard – $27260 plus $5180 ME&S

Using tokens

- NX11110 Mach 1 Product Design – $16,129 plus $3535 ME&S

- NX35100 NX Value Based Licensing 100 pack – $16,308 p.a.

- NX35050 NX Value Based Licensing 50 pack – $8,148 p.a

With a base of Mach 1 we do still not have a 100% functionality match, but you can see that the initial cost of the token based approach is more expensive ($32K to $44K). This illustrates the fact that tokens really appeal when there is a need for a wider set of addons.

That said, any company looking for new features and capabilities can see the benefit of spending a little more on tokens in order to gain the flexibility of being able to use a much broader product portfolio without further investment.

- This would be the case for a customer who has a dedicated pool of licenses but is looking at adding one or two more add-on modules.

- Purchasing a token pool on top of the existing licenses is a very cost-effective way of controlling future spend and adding flexibility to the existing capability. For small deployments start with at least 150 tokens per user, very large deployments with a large number of existing add-ons 50 to 100 tokens per user.

In the short term, you can generate revenue by selling the token pool concept on top of the existing licenses is a very cost-effective way of controlling future spend and adding flexibility to the existing capability. Enables customers to leverage new capabilities (available through tokens).

This model can improve competitiveness in sales situation as it allows us to offer a wider set of solutions than any of our competitors. Solving more of their engineering problems with our solutions.

Tokens are a product on the pricelist (just like any other product) so revenue is counted like any other revenue towards sales compensation.

Once a customer buys into a token strategy then it is important to maintain regular contact to ensure the tokens are being used and add more to the available token pool.

A major advantage of having tokens available is that they help a lot in competitive situations. For example:

- Often a lot of the value in our software, is within the software or niche options. That’s what gets designers excited about our solution.

- Tokens allows us to offer all our solutions without driving up discounts needed to align to customer budgets.

- Without tokens we would be forced to discount in order to include all those nice exotic options. Complexity and expense will start customers on the path to alternative vendors and / or large discounts.

- With Tokens you are able to offer access to a large pool of add-on products at a very aggressive price.

- When competing with a competitor who does not have tokens, we can force him to make his quote extremely expensive, by broadening the scope of the applications.

Tokens also enable you to differentiate in competitive situations upsell the value of a deal by enabling customers to access a larger set of capabilities for a very modest increase in cost. As mentioned before access to over $500K of add-on modules for a low annual investment.

It is important to remember we have more value-added add-on modules than our competitors, allowing customers to do more with their NX data, Value Based Licensing opens up a wide range of options from capabilities like Assembly Path Planning for Assembly/Disassembly checking to Molded Part Validation to ensure plastic parts are manufacturable. Examples:

- A medium size electronics company designing and building small devices that contain a mix of PCBs, complex Sheetmetal and sometimes use stylized plastic enclosures. They have 10 designers wanting to use NX:

- This mix would introduce the need for the following capabilities:

- Core modeling and design

- Advanced Sheet Metal design (NX Advanced Sheet Metal)

- Advanced styling and surfacing (NX Realize Shape)

- Ability to import PCB data (NX PCB Exchange)

- Ability to check plastic part manufacturability (Molded Part Validation)

- This mix would introduce the need for the following capabilities:

- This could be packaged together and delivered as:

- 10 x NX10110 – Mach 1 Floating

- 1 x NX30600 – NX PCB Exchange

- The mechanical design elements could all be delivered by a pool of tokens.

- Advanced Sheet Metal – 22 tokens

- Molded Part Validation – 12 tokens

- NX Realize Shape – 35 tokens

- Initially this mix could be met with NX35100 – NX Value Pack 100

- This assumes that there is not a great deal of concurrency. However, once a number of users start working on complex sheet metal parts or projects that require styling it is highly likely they will reach the limit to their token pool, so adding a NX35050 would give more flexibility.

- Heavy Equipment company needs 10 seats of NX plus capabilities for routing of Hydraulics Pneumatics, fuel, electronic harnesses, cabling:

- Cost of adding single seat of piping and tubing, cabling, and harness licenses is ~$70K US + 15.4K ME&S per year.

- To run the add-on applications concurrently 3 users would cost $210K US plus 45.2K ME&S.

- Tokens provide the same capability and allow for 3 users to run concurrently for $4756 per month (57K per year).

- In addition, the customer can leverage Mechatronics Concept Designer, Weld Assistant, Advanced sheet metal, realize shape for geometry, VDA checking, Human modelling and a lot more.

- Small machinery customer comparing cost of SolidWorks to NX:

- They need sheet metal, routing, and translators for Creo and V5, they also see MCD as a clear differentiator but buying everything is thought to be too expensive.

- Tokens provide all of this capability, plus much more for $3397 per month.

- Tokens provide all of this capability and enable you to set up a price /functionality discussion.

- A customer who doesn’t really know what balance of the add on modules they need in terms of quantities and would like to have some insurance that they can change their mind or use new capabilities they have not thought of so far:

- Tokens are an attractive option to this customer because of the flexibility they offer, you are not locking them down to either specific quantities or individual add-on modules. This can help you avoid situations where users are looking for loan or trial licenses to help them decide on the balance and mix.

We will include other compelling examples as the roll out of token licensing continues. There are opportunities in many industries including automotive suppliers, Mold tool and die shops, and machinery companies. Please send your ideas in so we can publicize your successes.

Moderate to high discounts can dramatically reduce the size of a deal.

- Tokens should be positioned as a way for customers to get access to capability for a fraction of the list price. You should cut the number of tokens before you cut the price.

- Tokens are a way for customers to rationalize license investments. They already represent substantial discounts over more traditional licensing approaches.

Customers using tokens, have access to a lot of new technology and might start asking questions related this broader set of applications.

- An increased focus on training and support is required.

- Sell training to maximize the value your customer will get from their investment and stay in contact with them to ensure they are successful.

- Our presales team need to understand and be able to show the wide variety of products in the NX Design token pool.

- Our support team have an internal process to connect experts who can support customers when they lack local experience of advanced or niche solutions.

Sales will grow their business by selling more tokens. So, while new software modules will be developed and can be made available under a token model… This will NOT automatically create new business, even if a lot of customers start using them.

- It is important to invest in the customer so that they can successfully use more capabilities which will lead them to reaching the limit of their token-pool and help you sell more tokens.

Here are some high-level guidelines for sizing token licensing systems:

- Token pools are most cost-effective when there is a wide variety of NX applications needing to be run. If four or more different applications are needed—say Routing Electrical, Assembly Path Planning, Human Modeling and STEP AP242—then tokens can be a cost-effective alternative to traditional per-seat licensing.

Remember, there is a price uplift on tokens versus equivalent per-seat licenses, so tokens are not always the best way to go. Consider proposing “mixed” licenses—part tokens, part per-seat—to give the customer the most flexibility at a good price. NX products that are just over a token “threshold” might be better purchased on a per-seat basis. Consider Mechatronics Concept Designer for NX (NX30535), which by itself requires 85 tokens. With the token count and with 100 tokens needing to be purchased (or, 85 tokens consumed from a larger token pool), it might very well be best if NX30535 is purchased on a per-seat basis as the token pool would rapidly become used. We recommend you run several scenarios—all per-seat, all tokens, and multiple “mixed” ones—to come up with the best proposal for your customer.

Consider “daily use” NX products versus “occasional use” NX products. Assuming the customer is making maximum use of his “daily use” products, tokens can be a very cost-effective approach for proposing multiple “occasional use” products. Tokens can also be useful for “flex times” when usage spikes upward for a short period of time; tokens enable the spike to be handled and, in the interim, provide “occasional use” flexibility.

Customers will ask about trading in their existing per-seat licenses for tokens. Given the 25% price uplift for tokens, plus the fact that they do not get 100% credit for what they already purchased, a “like-for-like” swap is not in the customer’s financial interest, unless the traded-in products are not being used. We recommend that you position tokens as being additive to the customer’s current environment.

Customer requirements and situations vary dramatically so it is hard to develop a document that covers every scenario in a short concise format. If you need further help after reading these notes, then call one of the following experts who will try to support you:

- GSM&S

- Richard Bush

- Product Management

- George Rendell, Mike Rebrukh, Boris Raskin

- Product Marketing

- Paul Brown

- Zone PfD

- Pavel Goncharov

Simcenter 3D

Simcenter 3D allows you to optimize your design cycle and stay up to date with market demands for smarter products that integrate mechanical functions with electronics and controls.

Here are some frequently asked questions regarding Simcenter™ 3D. If you still need help regarding your engineering software feel free to contact us for further assistance.

Simcenter 3D Motion software is an integrated, associative CAE tool that provides comprehensive mechanism modeling and analysis capabilities. You can use Motion to simulate and evaluate mechanical systems.

A motion body represents a rigid body in the mechanism that moves. When you create a motion body, you specify the geometry that defines that motion body. A motion body can be:

- An assembly component (recommended).

- A set of solid bodies, curves, points, and so on.

Joints represent connections between motion bodies. Without any constraints, motion bodies in a mechanism “float” in space with six degrees of freedom (DOF):

- Three degrees of translation (the X, Y, and Z directions).

- Three degrees of rotation (about the X, Y, and Z axes).

A joint driver assigns motion to a revolute, slider, or cylindrical joint or a point-on-curve constraint. It can only be a point on a rigid curve. Motion body drivers are available only with the Simcenter 3D Motion Solver. These types of motion body drivers are available:

- None (lets you remove an existing driver from a motion body)

- Polynomial

- Harmonic

- Function

- Control

- Profile

Motion Workflow

You might not have to perform all of these steps, depending on your situation.

| Step | Description |

|---|---|

| 1. Create a motion simulation. | You can create a standalone motion simulation or one that references a master part. |

| 2. Set your preferences and environment options. | Preferences and environment options are saved in your Simulation file. |

| 3. Create links. | For each mechanical feature in your model that moves, define a link. When you define a link, you can specify parameters such as mass properties, inertia, and initial translation and rotation velocities. You can also define flexible links, which may be useful when your analysis conditions include sharp impacts or sudden changes in motion, or if the component is flexible enough to affect the motion of the mechanism. |

| 4. Assign materials. | If necessary, assign materials to the bodies in your mechanism. Mass density is a key factor in the mass and inertia calculations used in a dynamic motion analysis. If you do not assign a material, the software assigns a default density value of 0.2829 lbs/in3 or 7.83*10–6 kg/mm3. |

| 5. Create joints and other constraints. | Joints constrain the motion between two links. You can also create other motion objects such as gear couplers and cables to further refine the motion between links. |

| 6. Define loads and contact. | If necessary, define forces, torques, springs, dampers, bushings, and contact. |

| 7. Add a motion driver. | A motion driver assigns motion to a link or a revolute, slider, or cylindrical joint. You can define a driver when you create a joint, or you can create a standalone driver that you can associate with a link or joint for a particular solution. |

| 8. Create motion events. | If necessary, create motion events to perform such tasks as detecting whether clearances between objects are violated, or measuring the distance between two points or objects. |

| 9. Create a solution. | Each solution can reflect different conditions for solving the mechanism. |

| 10. Solve the mechanism. | Solve the mechanism to generate results for analysis. |

| 11. Perform analysis tasks. | You can animate or articulate the mechanism, populate a spreadsheet with data from the results, create graphs, create a motion envelope, or perform other analysis tasks. |

A mechanism consists of geometry or assembly components that move cohesively. Defining a motion mechanism consists of these general steps:

- Specifying which components move and which are stationary.

- You identify the components that move by creating motion bodies.

- Constraining the motion of the motion bodies, which determines how they move relative to each other.

- Dynamic

- Static

- Time and step

- Articulation – quasi-static or kinematics, interactively driven

- Spreadsheet – quasi-static or kinematics, driven via a live Excel table

In Motion, you can add flexibility to a motion body. You can represent the deformation of the motion body either by discretizing the volume using a finite element method or using an analytical calculation based on the beam theory formulation using the spline beam method.

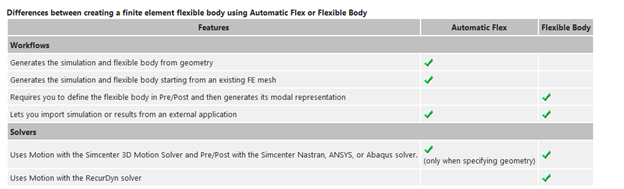

Using the Flexible Body ![]() , which lets you either use different solvers and solutions to define the flexible body model in Pre/Post or import a Simulation or results file from an external application.

, which lets you either use different solvers and solutions to define the flexible body model in Pre/Post or import a Simulation or results file from an external application.

Using the Automatic Flex ![]() , which automates the process of creating a finite element flexible body.

, which automates the process of creating a finite element flexible body.

Simcenter Femap

Simcenter Femap is the world’s leading pre- and post- processor for advanced engineering for finite element analysis.

Here are some frequently asked questions regarding Simcenter™ Femap™. If you still need help regarding your engineering software feel free to contact us for further assistance.

Femap has a built in associativity feature when creating entities. It can be difficult to recognize where the associativity is with a given entity. If the entity needs to absolutely be deleted such as a line, one method to remove the associativity is to use Modify > Associativity and remove the associativity of the nodes or elements from that particular entity. From there, the User can delete the entity using the Delete pulldown.

Users can quickly create a custom toolbar by right clicking in any of the toolbar space and selecting the “Customize” option which will open a new dialog window. Press “New” and specify the toolbar name. Users can then drag commands to the new custom toolbar to populate it by clicking on the “Commands” tab. Users can also add Keyboard shortcuts in the “Keyboard” tab. Users can also add custom API functions in the “User Commands” tab. Once satisfied with the toolbar, click “Close”.

If users wish to turn off their new custom toolbar, they can right click the “Customize” option in the toolbar space and check the box to hide it under the “Toolbars” tab.

FEMAP 11.1 and later add a new graphics architecture to improve graphics performance of both the initial draw and dynamic rotation. This requires OpenGL 4.2. If your graphics card supports OpenGL 4.2, FEMAP will have a message in the message window such as:

- Full OpenGL Hardware Acceleration (Double Buffered).

- Your graphics card supports OpenGL 4.2.

If your graphics card doesn’t support OpenGL 4.2 or later, check with your graphics card vendor to see if there is an updated graphics driver with OpenGL 4.2 support. If your graphics card does support OpenGL 4.2 or later, you can turn on Performance Graphics.

- Choose File > Preferences.

- Select the Graphics tab.

- Check the box next to Performance Graphics.

- Click OK.

- Geometry: *.asm* , *.catp*, *.dlv, *.dxf, *.exp, *.igs, *.jt, *.mdl, *.model, *.par, *.prt*, *.psm, *.pwd, *.sat, *.sldasm, *.sldprt, *.step, *.stl, *.stp, *.x_b, *.x_t, *.xmt_txt

- Databases: *.ans, *.bdf, *.blk, *.cae, *.cdb, *.d, *.dat, *.fno, *.inp, *.nas, *.neu, *.neu, *.nid, *.out, *.pat, *.sdb, *.t16, *.unv, d3*

- Results: *.cae, *.csv, *.dis, *.els, *.f06, *.f11, *.fil, *.fin, *.fno, *.lis, *.neu, *.nod, *.onf, *.op2, *.out2, *.prt, *.rst, *.rth, *.sdb, *.sof, *.t16, *.xdb, d3*

Some customers have noted that CBUSH spring forces or Grid Point Force Balance data (used for Freebody) was not appearing in FEMAP when the model was run from FEMAP, but the did show up when manually importing the results.

The workaround is to manually import the .op2 file (File > Import > Analysis Results). There is no more work being done to add new features to the .f06 file reader, only to the .op2 file reader. Starting with 11.1, the plan is to only use the .f06 file reader when the results destination is set to “1..Print Only”. The .op2 file reader will be used wen Results Destination is set to “3..Print and PostProcess” and you will still get all of the info, warning and error messages along with other stuff from the .f06 file (for instance, modal participation factors) which can’t be found in the .op2 or .xdb file.

Up through FEMAP 11.0, if you have the Results Destination set to “0..Default”, “2..PostProcess”, “5..Punch and Postprocess”, or “6..XDB”, FEMAP will read the results data out of the .op2 file (or the .xdb file when “6..XDB” is used). In this situation, all the results will be read. However, if you set the Results Destination to “3..Print and PostProcess”, FEMAP will put the results into both the .f06 files and the .op2 file. When FEMAP does the auto import of results, if it sees results in the .f06 file, it uses that for all results, and never imports results from the .op2 file. The problem happens because the FEMAP .f06 file reader, being older legacy code, does not support some items, including CBUSH forces or Grid Point Force data.

MSC input is a bit different, but it's not to hard to convert the input file with a text editor:

| NX | MSC | Function | Notes | Conversion |

| BCBODY1 | Defines deformable body | References BSURF | Create a separate BCBODY1 for each BSURF. To keep it simple, use the same id as the BSURFBCBODY1,id,,2D or 3D,,bsurf-id | |

| BCTSET or BGSET | BCTABLE1/ BCONECT | Defines connection between bodies | BCONECT references BCONPRG/BCONPRP, BCTABL1 references individual BCONECT contact pairs | Break BCTSET/BGSET up into individual pairs to convert to BCONECTs. This uses the ids of BCBODY1, not BSURF. If you used the same ids for BCBODY1 as BSURF, then you shouldn’t need to worry about ids. Give each BCONECT pair an ID. Create a BCTABL1 that lists the ids of the BCONECT pairs. If you have friction, that needs to go on the BCONPRP, which is otherwise optional.BCONECT,pair-id,bconprg-id,bconprp-id,slave-id,master-idBCTABL1,table-id,pair-id1,pair-id2,pair-id3,etc. |

| BCRPARA | BCONPRG/ BCONPRP | Defines top/bottom and offset for NX | BCONPRG,id,,IGLUE,3 turns on glued contact for the BCONECT.BCONPRP,id,,FRIC,value turns on friction for the BCONECT.BCONPRG also has options for top vs. bottom face, and shell thickness | |

| BSURF | BSURF | Defines elements that make up contact surface | No change needed | No change needed |