Revolutionize Your Production Capabilities With Saratech Manufacturing Solutions

Optimize your processes and bring your innovative ideas to life! Get Started with a free consultation.

Our Manufacturing Solutions & 3D Printing Capabilities

Manufacturing has advanced greatly in the last few years with the explosion of new and affordable 3D printing technologies. From strong plastics, to composites and metal, companies have many options when it comes to manufacturing. From the traditional CNC machining to new additive manufacturing, or a hybrid approach, Saratech will assess and recommend the solution that is the right fit for your organization.

Saratech Manufacturing Center of Excellence Capabilities Includes:

Develop Solutions to Your Manufacturing Challenges

We provide CNC programming solutions to technical challenges including methodology, tool design and actual programming.

Assist With Technical Needs for Post Processors & Other Software Related Support

Development, revision, correction, and adaptation.

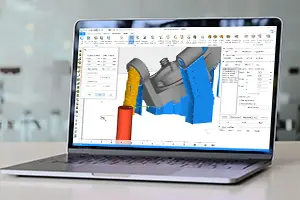

Siemens NX CAM Software Implementation & Assistance

From license installation to technical training and mentoring Saratech is your one-stop shop for Siemens manufacturing software needs.

Manage Large & Medium Manufacturing Projects

We can manage large scale design and build projects, providing full visibility technical project management of your manufacturing projects.

Manufacturing & 3D Printing Solutions

Optimize your 3D printing with Materialise Magics, the most powerful data and build preparation software. Magics simplifies making a 3D design file printable by providing CAD and mesh tools in one solution. Enjoy enhanced efficiency, advanced control, and reliable support throughout the entire workflow—from importing files to slicing builds. With features like automated repairs, lattice structures, and intelligent nesting, Magics ensures superior quality and accuracy. Its technology-neutral platform caters to various materials and technologies, making it the ultimate tool for streamlined 3D printing processes.

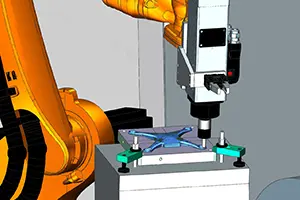

Saratech has vast experience in designing and building large and complex assembly and handling tools. We use best industry practices and a well-defined validation process. Our fabricators are some of the best suppliers in the industry and are AS9100 and ISO9000 certified. Our expertise in 3D printing allows for an improved lead time delivery.

Markforged revolutionizes 3D printing with advanced, affordable solutions that produce industrial-quality parts. The Metal X 3D Printer excels in metal printing, using Atomic Diffusion Additive Manufacturing (ADAM) for efficient production. Their Eiger software simplifies management and reduces waste. The robust Industrial Series offers laser precision and continuous filament fabrication, while the versatile Desktop Series creates strong, high-quality parts. With innovative materials like carbon fiber and Kevlar, Markforged meets diverse manufacturing needs, setting a new standard in 3D printing.

BigRep, a trailblazer in large-scale additive manufacturing, offers high-quality, German-engineered 3D printers that make industrial-scale printing easy and affordable. Winners of the German Brand Award, BigRep provides solutions like the BigRep ONE, which features the largest FFF build volume on the market, and the BigRep STUDIO G2, designed for durable, large-format parts. The latest addition, the BigRep PRO, combines speed and precision for industrial applications. Partnering with BASF, BigRep delivers advanced 3D printing materials, ensuring reliable, high-quality results for diverse industries.

Ensure Seamless Operation & Maximum Uptime While Delivering High-Quality Parts Faster Than Ever Before With Saratech’s CNC Integrated Simulation & Verification (ISV) Kits.

Additive Manufacturing Case Studies

Siemens software & HP 3D Printing systems join in a complete, closed-loop environment, streamlining the development of 3D-printed parts.

Innovative Engineering & Additive Solutions for a Streamlined Pipe Drilling & Stopping Process

BigRep's 3D printing technology helped Ford see a complete return on investment and allowed faster innovation.