Reinvent Your Manufacturing Method With Next-Generation CAM Software.

Siemens NX CAM Software for Manufacturing

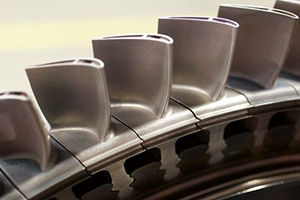

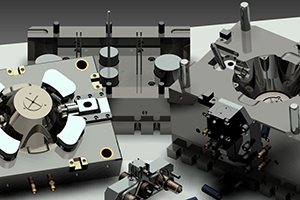

Reinvent your manufacturing method with next-generation CAM software. NX has been adopted across many industries, delivering proven capability for manufacturing in the aerospace, automotive, medical device, mold and die and machinery industries. NX provides a complete set of NC programming capabilities in a single CAM system as well as an integrated set of manufacturing software applications. These applications facilitate part modeling, tool design, and inspection programming – all based on proven NX technology.

Benefits of NX CAM Software

- Reduce as much as 90% on your feature-based machining programming time

- Program CNC tools, control robotic cells, run 3D printers and monitor quality

- Manage data from 3D part models, setup sheets, tool lists, and CNC output files

NX CAM Software Capabilities

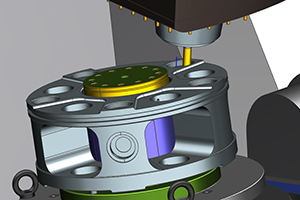

Make better parts faster with comprehensive and integrated NC programming capabilities in a single system. NX CAM enables the use of consistent 3D models, data, and processes to seamlessly connect planning and shop floor operations with a digital thread. Produce complex parts with fewer actions and setups - while reducing costs and delivery times.

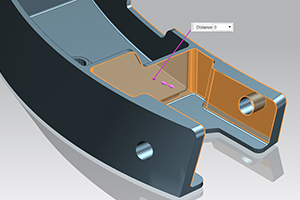

Meet demanding requirements for dimensional accuracy by establishing an efficient data-driven quality control process. A key NX CAM advantage facilitates integrated CMM inspection programming, shop floor execution, and measured data analysis so you can deliver high-quality products.

Robotic Automation

Prepare Part Models for NC Programming

NX CAM Software Case Studies

AUTOMOTIVE

Learn how this leading automotive component manufacturer increased productivity by 50 percent and reduced manufacturing time and costs with NX CAM.

MARINE

Learn how Sunseeker optimized their yacht design, parts procurement, and build with NX and Teamcenter.

NX CAM Software Tutorials