Accelerate Productivity & Outpace Competition with Saratech's Manufacturing Services

Transform Your Manufacturing Operation with Saratech: Expert Services & Innovative Solutions

At Saratech, we excel in being the premier partner for all your manufacturing needs. Our extensive industry expertise, combined with best practices and a wealth of experience across diverse machines and quality systems, ensures we help you produce more parts faster, with superior quality and consistency. With a team of highly skilled engineers and accomplished leaders, we bring a rich history of success and extensive CNC programming knowledge to the table.

We offer comprehensive services beginning with an onsite assessment of your manufacturing operations. Our experts will visit your facility to understand your processes, products, and requirements, identifying opportunities for improvement and cost savings. We then develop and implement these improvements, working closely with your team to demonstrate, train, and optimize your processes for better efficiency, lower costs, and reduced risk.

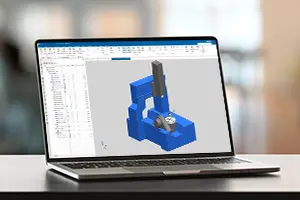

Our capabilities include NX CAM software training and postprocessor development, advanced CNC programming, and innovative 3D printing solutions. We create custom post processors, build simulation machine kits, and program new parts optimized for your machines and tools. Our goal is to optimize your manufacturing process, driving improved TAKT times and reducing WIP cycle times.

Let Saratech show you how we can transform your manufacturing operations and elevate your production capabilities. Together, we can achieve greater efficiency, higher quality, and unmatched success.

We Help Our Customers Manufacture More Parts in Less Time With Higher Quality & Greater Repeatability.

INDUSTRY EXPERTISE

- Best practices

- Experience on a wide range of machines

- Tooling & handling equipment

- Quality systems

ENGINEERING KNOW HOW

- Experienced aerospace engineers

- Experienced leadership team

- Long track record of success

- Extensive CNC programming experience

Value & Benefits of Our Manufacturing Services

Comprehensive Onsite Assessment of Your Manufacturing Operation

Saratech's Manufacturing Engineers will visit your facility to thoroughly understand your processes, products, and requirements, identifying opportunities for improvement and cost savings. We will provide a detailed report outlining potential enhancements, cost savings, and profit-boosting strategies.

Development & Implementation of Identified Improvements

Saratech Engineers will collaborate with your team to demonstrate, train, and implement process improvements, enhancing efficiency, reducing operational costs, and mitigating risks. Our hands-on approach ensures a seamless transition, equipping your workforce with the knowledge and tools necessary to sustain the improvements long after our engagement.

Tailored Solutions for Your Operations

We offer cutting-edge solutions to optimize your manufacturing processes. Our custom post processors and simulation machine kits enable advanced CNC programming for efficient part production. Additionally, we provide innovative 3D printing solutions that expedite lead times and reduce costs. Whether leveraging our expertise in CNC machining or our capabilities in additive manufacturing, we deliver tailored approaches to streamline your operations and drive productivity gains.

Post-Activity Review

A comprehensive Post-Activity Review ensures your organization reaps full benefits from our collaboration. We'll assess implemented improvements with your management team and present metrics demonstrating their bottom-line impact, quantifying our partnership's value. Through continuous monitoring and optimization, we'll adapt strategies as needed to sustain realized benefits over time. Our approach drives long-term success from improvements implemented today.

Expert Guidance & Support

Get access to a team of experienced aerospace engineers and industry leaders who possess extensive CNC programming expertise. With a proven track record of success in manufacturing optimization, our skilled professionals can leverage their deep knowledge and real-world experience to streamline your operations, enhance efficiency, and drive measurable improvements across your production processes.

Increased Productivity & Quality

Achieve unprecedented productivity gains. Our solutions enable the ability to manufacture more parts in less time, leveraging optimized processes for higher throughput and greater repeatability. We focus on improving TAKT times and reducing WIP cycle times, maximizing efficiency throughout your operations. By harnessing our capabilities, you can increase your manufacturing velocity while maintaining stringent quality standards, ultimately boosting your competitiveness in the marketplace.

Our Manufacturing Capabilities

Saratech Application Engineers will demonstrate unused capabilities of NX CAM software and train your team in implementing the aspects most valuable to your operation. Some examples include:

- Engineering Change Order Process

- Feature Based Machining

- Part Templates

Our experienced Application Engineers will build post processors, simulation kits and train your teams to drive quality results with complex and expensive machines. Our deliverables go straight to your bottom line.

- Build Post Processor - We create custom post processors for your complex machines

- Build Simulation Machine Kits - We build full machine kits to provide simulation and verification

- Optimize Machining Processes - We program new parts optimized for your machines and tools

- Advanced Machine Programming Support - We program your complex parts

Our Manufacturing Center of Excellence has very experienced team members that can help optimize your manufacturing process (driving improved TAKT times) and process optimization to reduce WIP cycle times.

- Project Management - Manage your subcontract manufacturing and assembly jobs effectively

- Manufacturing Engineering - Manufacturing process design and detailed planning

- Manufacturing Environment - Create a full environment for your machines, cells or entire processes

- 3D Printing - Consult in the application of 3D printed tooling solutions to expedite lead time and reduce cost

In the ever-evolving landscape of aerospace manufacturing, innovation and collaboration have become the key drivers of success. Saratech proudly announces an exciting collaboration with Stretch Form Corporation (SFC), a shining example of how two companies, each excelling in their respective fields, can come together to create groundbreaking solutions.