Speed Up Your Product Development With 3D Printing Services From Saratech

Get Started With a 3D Print Quote

Leading Edge Companies Partner With Saratech to Develop Groundbreaking - State of the Art, Products.

Improve Your Product Development Experience With Saratech

We provide tools, engineering expertise, and services that will optimize your engineering processes to accelerate product development and speed up your time-to-market.

3D Printing Team Support

Prototype Print, Capabilities Verification Print, & Production Overflow Print

Our 3D printing team offers top-notch expertise and support to optimize your engineering processes and accelerate your time-to-market.

Engineering Know How

Experienced Engineers With a Long Track Record of Success

We have experienced aerospace engineers, experienced leadership team & extensive CNC programming experience.

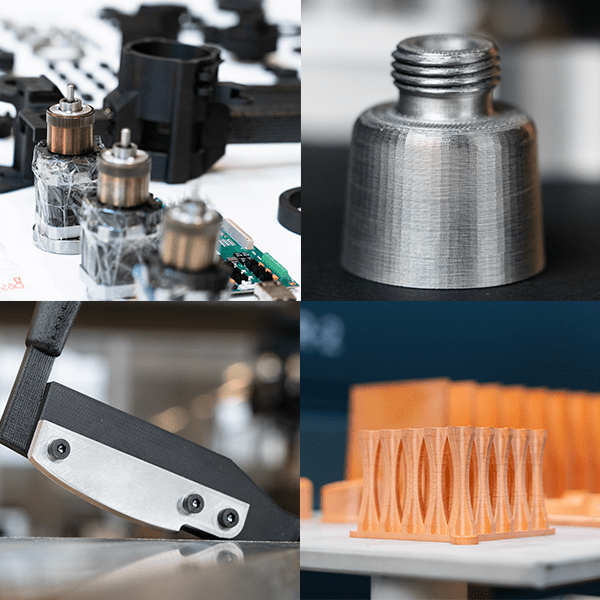

3D Print Services Capabilities

Prototype Print, Back Up 3D Print Service, & Design Support

We can print your prototype for design validation and testing, supplement your 3D printing capabilities and alleviate supply chain bottleneck, and we will work with your engineers to optimize your designs for 3D printing.

Get Your 3D Printing Quote

Partner with Saratech to print your prototype for design validation and testing, supplement your 3D printing capabilities, and alleviate supply chain bottlenecks. Fill out the form below to get started with a 3D Printing quote.

A Collaboration of Engineering Services & 3D Printing

In the ever-evolving landscape of aerospace manufacturing, innovation and collaboration have become the key drivers of success. Saratech proudly announces an exciting collaboration with Stretch Forming Corporation (SFC), a shining example of how two companies, each excelling in their respective fields, can come together to create groundbreaking solutions.

3D Printing Technologies & Materials

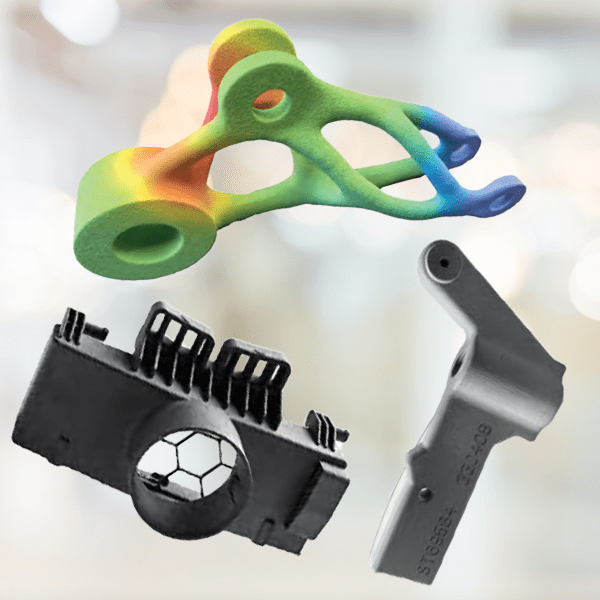

MJF Nylon Parts

Test your designs before they go into production using Nylon PA12 for accurate and functional prototypes. This technology enables more complex designs that don’t require support structures. Need low volume production? MJF printing offers similar parts to injection molding without the tooling costs. Have an application that uses color? Our HP MJF technology can print in full color to help your parts stand out.

Print PA12 parts up to 380x284x380 mm (15x11x15 in)

High-Strength Composite Parts

Save time on the mill by printing strong carbon fiber composite parts with our Markforged technology. This true composite material is strong enough to replace aluminum in many applications. The technology has great accuracy and excellent surface finish. Perfect for end-of-arm tooling and non-marring jigs and fixtures.

Print nylon parts with embedded carbon fiber, fiberglass, or Kevlar up to 330x270x200 mm (13.0x10.6x7.9 in)

Metal Parts

3D printed metal parts can unlock new design complexity. Reduce machining lead time with 3D printing. Produce custom heatsinks in copper or build custom tools using hard tool steel. Metal printed parts are fully machinable and weldable.

Print Copper, stainless, Inconel, and tool steel parts up to 235x68x69 mm (9.2x2.6x2.7 in)

Large-Format Plastic Parts

Larger parts can be printed with our BigRep 3D printing system to produce plastic prototypes as large as 500mm by 500mm by 1000mm. This technology is great for automotive applications such as test fit panels and interior parts, as well as large jigs and fixtures.

Print PLA, PETG parts up to 500x500x1000 mm (19.7x19.7x39.4 in)

Bring Your Ideas to Life With Architectural 3D Printing Services From Saratech. Our Team of Experts Will Translate Your Models Into Finished Products With Ease.

Why Architects Should Use 3D Printing for Models

3D modeling is essential to create a better visualization of your models or structural designs. With 3D printing, the opportunities are endless to create fast turn, highly detailed complex models. Architects can use 3D printed models to quickly and easily demonstrate proposed buildings as well as show how structural elements work together.

Our 3D print services include full-color 3D printing, CAD drafting, model evaluation, 3D print file preparation, 3D print file repair, and more. Our methodology is to provide the outcome you desire on time and on budget.

What We Offer

3D EXPERT ASSISTANCE

Our team is proficient in 3D Modeling, Architecture, Engineering, & Industrial Design.

FAST TURN AROUND

We provide professional, fast, and high quality 3D printing.

FULL-COLOR 3D PRINTED MODELS

Produce realistic colorful models with accuracy.

PRINT OR BUILD MODEL OF ANY SIZE

Our 3D printers can build small to large-scale 3D printed parts.

COST EFFECTIVE CUTTING-EDGE PRODUCTION SOLUTIONS

Our 3D experts and cutting-edge production methods save you time and costs so you can focus on model creation.

Additive Manufacturing Case Studies

Siemens software & HP 3D Printing systems join in a complete, closed-loop environment, streamlining the development of 3D-printed parts.

Innovative Engineering & Additive Solutions for a Streamlined Pipe Drilling & Stopping Process

BigRep's 3D printing technology helped Ford see a complete return on investment and allowed faster innovation.