Discover the MBSE Revolution in Systems Engineering

Watch our Customer Enablement Series (CES): Top 5 Ways to Get Started With MBSE!

MBSE Simplifies the Development of Complex Products

Today’s complex and highly integrated products require a systems-driven approach to product development that combines systems engineering with an integrated product definition and the ability to unify your product development framework with your manufacturing and shop floor operations.

What is model-based systems engineering?

According to the International Council On Systems Engineering (INCOSE), “Model-based systems engineering (MBSE) is the formalized application of modeling to support system requirements, design, analysis, verification, and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases.”

MBSE is an effective approach that enables engineering teams to efficiently and collaboratively develop complex, integrated products with minimal errors and delays.

Why is model-based systems engineering important?

Traditional product development no longer works in a distributed engineering environment. You can’t do it all manually anymore, especially when the people you need to work with (your supply chain) are now globally dispersed. MBSE allows for integration management throughout the entire product development process and provides competitive advantage over your competitors.

Utilizing model-based systems engineering brings various benefits like improving program execution, speeding up product development, and allowing errors to be caught early.

Key Pillars to Model-Based Systems Engineering

To facilitate model-based systems engineering, your company needs to look at several key factors:

Functional Networks

A series of networks that facilitate the functional breakdown of your entire product, including requirements allocated to the product’s various functions, logical relationships defined between these functions and the physical implementation of these functions.

Consistent Process Framework

A framework that crosses all your product development and manufacturing domains and integrates your functional network through change and issue management, configuration management and schedule management –unifying your mechanical, electrical, software, and electronic development domains with your process planning and plant operations.

Advanced Modeling and Simulation

The ability to derive engineering requirements from user needs and validate that your engineering specifications fulfill these needs early in the product development process.

Open PLM Environment

A PLM-driven infrastructure where your home-grown and commercial software tools can be easily integrated and efficiently leveraged.

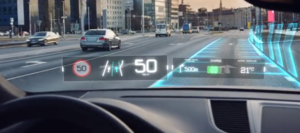

Intuitive User Experience

The ability to enable all your product development and manufacturing/production stakeholders to access all of the product, process and manufacturing information that they need to intuitively understand your product as a complete system – as well as to help these users, depending on their task and role, proactively leverage this information in the context of their job tasks.

Getting Started with Model-Based Systems Engineering (MBSE)

Many organizations and engineers do not feel comfortable with the application of MBSE. They feel overwhelmed and not even sure where or how to start. Let us help. Fill out the form below to begin: