Discover BigRep 3D Printers and Solutions

As recent winners of the German Brand Award, BigRep is a trailblazing leader in large scale additive manufacturing. Experience high-quality German-engineered products that make manufacturing objects as easy and affordable as possible.

Find the Right BigRep 3D Printing Solution for Your Needs

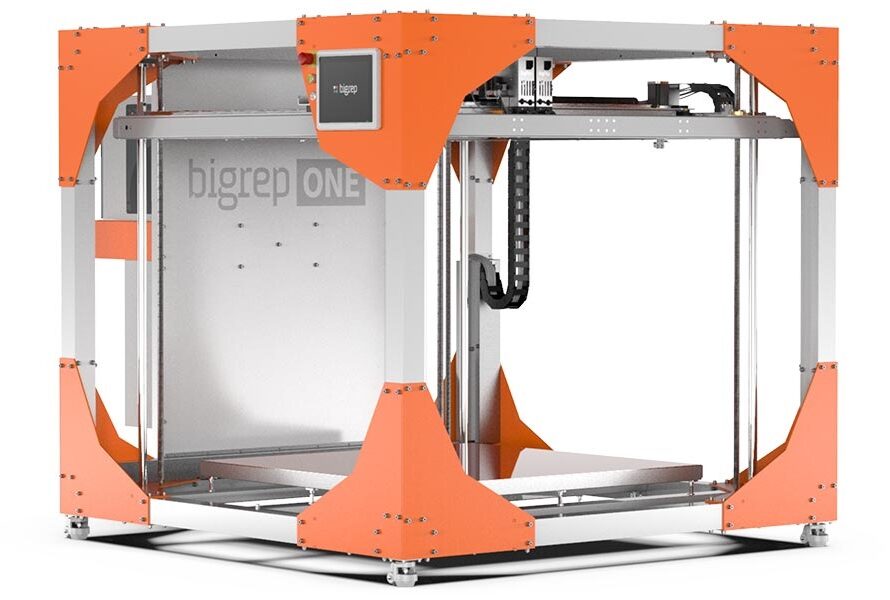

BigRep ONE 3D Printer

Achieve Affordable & Reliable Large Scale 3D Printing

Meet the BigRep ONE created by BigRep - recent winners of the German Brand Award 2018. BigRep ONE is a German-engineered large-scale 3D printer designed to work around the clock with unfailing reliability. Learn how the ONE can give you better quality, higher speed, and increased safety.

See How the BigRep ONE Works

The BigRep ONE has the most substantial FDM build volume on the market, so you never have to scale down your designs. The ONE works perfectly in automotive or aerospace industries, as well as entertainment, or concept modeling. With a capacity of over one cubic meter, the BigRep ONE can bring all your big ideas to life.

The BigRep ONE was created to make industrial 3D printing of large-scale objects as easy and affordable as possible. As the winner of the German Design Award 2016, the BigRep ONE continuously drives innovation in a diverse range of industries and applications.

BigRep ONE Features

Check out the unique features and benefits of the award-winning BigRep ONE.

THE FRAME CONSTRUCTION

An open-format with the best possible view of the print job ensures that monitoring the quality and progress of the object is hassle-free at all times.

THE PRINT HEADS

For unmatchable flexibility when printing, these print heads were created by BigRep's in-house team and optimized for large-scale printing projects.

THE PRINT BED

Reduce prep time considerably with BigRep ONE's integrated automatic inductive sensor which allows the print bed to be leveled quickly and effortlessly.

THE BUILD VOLUME

With a capacity of over one cubic meter, the BigRep ONE provides the largest FFF build volume currently available on the international market.

THE SPOOL HOLDER

Designed to fit all standard spool sizes, this spacious and flexible spool holder can hold several spools up to 8 kg.

THE GRAPHICAL USER INTERFACE

An easy and intuitive user interface can help you check print progress via webcam, resume print after a power failure, and more.

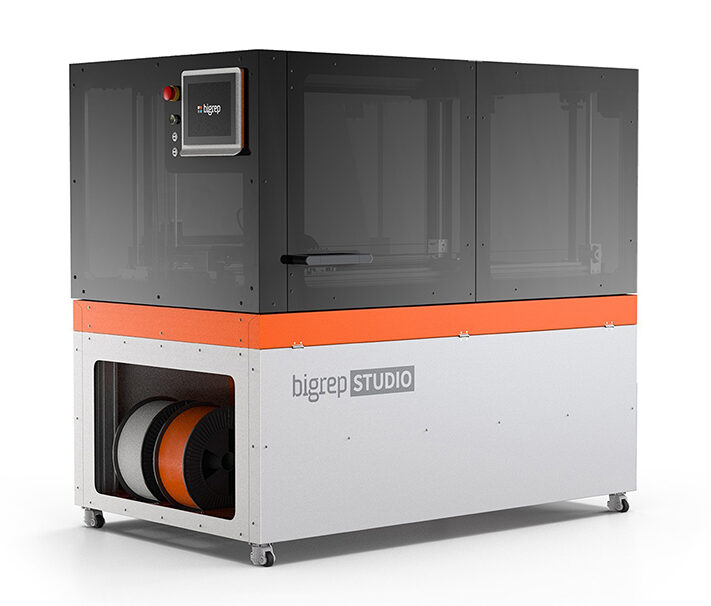

BigRep STUDIO G2 3D Printer

Create Durable Large-Format Parts

Discover the ideal German-engineered 3D printer capable of creating durable large-format parts efficiently and affordably. As the winner of the prestigious 2018 German Innovation Award, the BigRep STUDIO G2 continues to deliver exceptional results for all types of industry professionals.

See How the BigRep STUDIO G2 Works

Bring your innovative ideas to life with the STUDIO G2. An enclosed print envelope maintains a controlled temperature and boasts a print volume of 500 mm x 1000 mm x 500 mm. The STUDIO G2's made to handle abrasive and engineering-grade materials.

The BigRep STUDIO G2 enables continuous printing of large-format objects with nylon and other various engineering-grade materials. The dual extruder equipped with two 0.6 mm hot ends is made for printing high-resolution, complex parts in an efficient, cost-effective process. From design labs to productions floors, the STUDIO G2 is optimal for all workspaces in its sleek space-conscious frame.

BigRep STUDIO G2 Features

Unlock new capabilities with BigRep STUDIO G2's amazing features!

ENGINEERING GRADE MATERIALS

Print with abrasive, engineering-grade materials at maximum speed and high resolutions with the STUDIO G2.

FULLY ENCLOSED ENVIRONMENT

With a temperature-controlled build envelope, your engineering-grade materials are always in an optimal insulated environment.

INDEPENDENT TEMPERATURE CONTROLS

Ensure your engineering-grade materials remain dry in a temperature-controlled environment with the STUDIO G2's filament chamber.

EASY AND INTUITIVE

Achieve a rapid, hassle-free start to printing with the easy to use BigRep "BLADE" slicing software. The new slicer allows for greater control of printing parameters.

OPTIMAL PRINTING TEMPERATURES

Reduce prep time and achieve higher heat dimensions reaching 100°C for better adhesion to the print bed, yielding a variety of high-quality materials.

BIG ENOUGH FOR ANY IDEA

With an astounding build volume of 500 mm x 1000 mm x 500 mm, you can create large-format engineering-grade parts fast at high resolution.

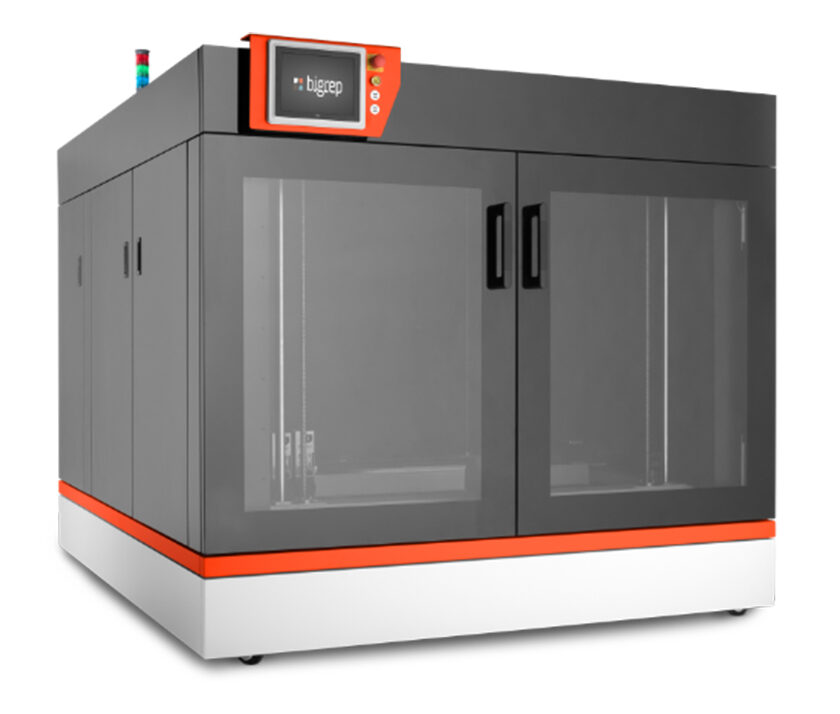

BigRep PRO 3D Printer

Large Scale & German-Engineered

Get to know the latest addition to BigRep's range of additive manufacturing solutions - the BigRep PRO. The PRO delivers large-format prints with exceptional speed and precision for industrial solutions.

See How the BigRep PRO Works

The BigRep PRO ensures innovators can manufacture the applications they need, in large scale. The PRO was inspired by the ONE and STUDIO 3D printers, both winners of multiple awards including the German Brand and German Innovation Awards 2018.

Whether it’s functional prototypes, composite tooling, or end-use products, the PRO exceeds expectations. With a range of new features, including a state-of-the-art Bosch CNC system, new Metering Extruder Technology (MXT), and an enclosed build chamber, the PRO delivers future-ready products.

BigRep PRO Features

Explore new frontiers of large-format 3D printing with the BigRep PRO's extensive features and capabilities.

THE BUILD PLATFORM

Enable countless application possibilities with a build envelope of one cubic meter capable of 3D printing large-scale industrial objects.

THE ENCLOSED FRAME

Shielded printing allows for even temperature control, and glass doors offer an optimal view of the print.

THE INSULATED FILAMENT CABINET

Achieve uniform temperature throughout the filament cabinet with a humidity-controlled spool chamber and air circulation fans for an optimal printing environment.

THE MXT

Introducing metering extruder technology (MXT) - an exceptional extruder that allows for ultimate control on materials deposition so users can achieve the highest quality for every application.

THE PRINT BED

Reach optimal adhesion in your printing process with BigRep PRO's heated print bed. An integrated inductive sensor allows for semi-automatic leveling of the print bed.

THE CNC SYSTEM

Control the entire printing process from start to finish with state-of-the-art Bosch CNC motion-control system. Ensure maximum responsiveness, accuracy, and closed-loop control.

Materials

Filaments

Partnering with BASF, the world's leading chemical company, BigRep delivers the most advanced 3D printing materials for a wide range of custom use cases. Achieve uniform diameters, roundness, composition, and color across a broad spectrum of filament spool sizes from 750 grams to 8 kilograms.

PETG

The ideal material for 3D printing projects requiring strength, toughness, and thermal resistance in a filament.

PA6/66

This light-weight and resistant 3D printing filament is an excellent candidate for most industrial applications.

PRO HT

An environmentally friendly thermoplastic that has a significant increase in temperature resistance compared to the average PLA, making it ideal for end-use applications.

TPU

Check out this flexible filament with high durability and exceptional chemical resistance.

PLA

Use this affordable and versatile filament for demanding industrial projects such as printing large objects for architecture or construction fields.

PVA

This water-soluble support filament is perfect for printing complex, ready-to-use prototypes.