Our CAE Consulting Services

Demand for computer-aided engineering (CAE) tools is booming as the technology becomes more sophisticated. Increasingly powerful computing tools have enabled the development of advanced software that can accurately predict how products will behave under various physical conditions.

Originally used in aerospace, CAE has been adopted in a wide range of industries, including automotive, consumer products, electronics, machinery and medical devices. CAE is used to test product designs and develop virtual prototypes, making it possible to identify potential design issues early. It also allows product developers to troubleshoot problems with existing products.

Saratech’s CAE consulting services can help manufacturers maximize the value of performing analysis prior to product tooling decisions and manufacture. Our engineers have extensive experience developing CAE models and interpreting the data, saving our customers money and helping them get better products to market faster.

What Are CAE Consulting Services

CAE consultants begin with a 3-D CAD model of the product or component along with the material properties and load conditions. The consultant will also want to know what information is most important to the customer so that the analysis model can be simplified.

The deliverable is a report providing a description of the input data used and detailed analysis of stress, fatigue life and other factors, and may also include dynamic, vibrational and thermal loading conditions. The consultant will summarize the findings and offer comments, suggestions and conclusions.

The Value of CAE Consulting Services

CAE can help reduce costs and improve product and system performance. It can also minimize the need to build and test physical prototypes. However, CAE tools can be complex, requiring experienced engineers to obtain useful results from the technology and properly analyze the data. CAE experts will know what assumptions can be made so that the analysis addresses the customer’s primary concerns.

Experienced CAE consultants can help design engineers make better decisions and expedite product development. They enable designers to efficiently address complex engineering problems, validate component designs and evaluate performance and different operating conditions.

Saratech's Area of Expertise

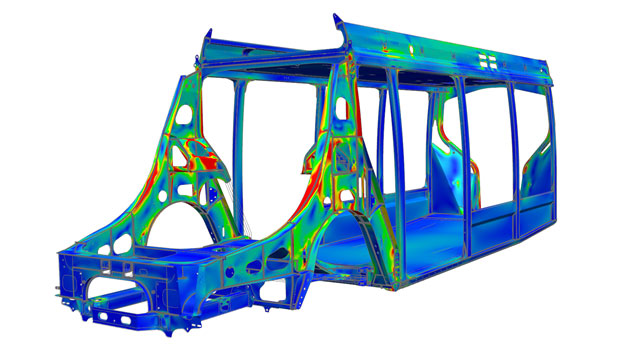

Structural Analysis

Structural Analysis evaluates the stresses placed on a component and the potential for fracture or deformation under various operational conditions. The objective is to determine if the component can safely withstand the forces acting against it.

Multibody Dynamics

Multibody dynamics calculates loads on various parts of a system to predict motions and displacements. It helps product engineers determine whether a mechanism will work as designed and what would happen if a part breaks.

Dynamic and Vibrational Analysis

Dynamic and vibrational analysis computes the resonant frequencies of a structure and determines the shape of the structure at each frequency. It goes beyond traditional static analysis to help product engineers better predict the behavior of a system.

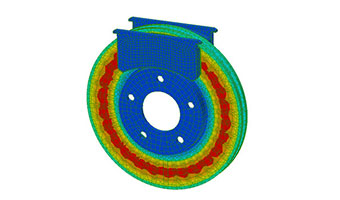

Thermal Analysis

Thermal analysis determines the transfer of heat in a component through convection, conduction and radiation. Product engineers need an understanding of heat loads and temperature distribution to reduce the risk of failure due to thermal stress.

Why Choose Saratech?

Full Spectrum Service

Saratech offers the entire spectrum of CAE consulting services, from conceptual design to detailed analysis to testing and even manufacturing. We coordinate all aspects of the project, freeing our customers to focus on product development.

Time and Cost Effective

Our team is very schedule-driven, ensuring that every project is completed on time and within budget. Our engineers have extensive expertise in CAE tools, enabling us to identify potential problems and deliver actionable information.

Resources

Whitepaper: What to Look for in Your Service Provider Read the following whitepaper to gain critical insight into what to look for in your service provider.

Whitepaper: Improving Your Company's Simulation Capabilities and Processes for Business BenefitThis whitepaper introduces a general framework used to address the top simulation issues companies experience.