End-to-End Design and Manufacturing Solution for Composite Parts

The Fibersim portfolio of software allows the side-by-side design and manufacturing methodologies necessary to engineer innovative, durable, and lightweight composite products. The open architecture of Fibersim provides a specialized engineering environment to create a composite digital twin in NX, CATIA, or CREO.

Fibersim will assist you through the whole product development process. This includes initial sizing requirements, detailed laminate definition, layup simulation, documentation, manufacturing data feeds, and quality verification. Fibersim will help your engineering team make smarter decisions and better products by transforming your CAD system into a composites development environment.

Benefits of Fibersim

- Reduces the cost of product development

- Reduces the time it takes to develop products

- Optimizes composite parts

- Eliminates any product defects or failures

- Creates consistent high-quality products

Capabilities

Fibersim software offers an open architecture that supports multiple CAD systems and engineering tools. It can automate design and definition as well as support multiple composite design and manufacturing processes.

Design

Design

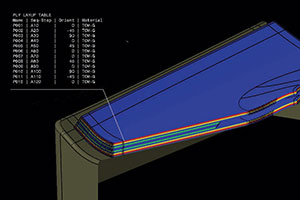

For design engineers, Fibersim facilitates the authoring of composite design data to create a complete 3D product definition. It will provide tools that automate design tasks that are repetitive. Fibersim will also automate different levels of visual and data representations to best suit to engineering task at hand. It also provides a variety of deliverables such as model based definition formats, enterprise reports, and design documentation.

Manufacturing

Manufacturing

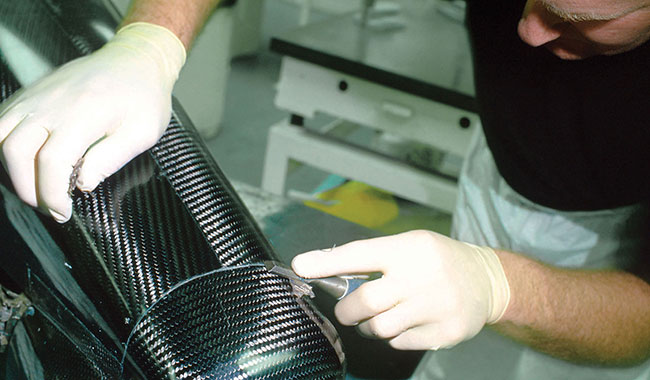

For manufacturing engineers, Fibersim facilitates the creation, management, and communication of the manufacturing definition by consuming the design data and generating an associative manufacturing model. The software provides tools that automate design for manufacturing, such as splicing, darting and ply edge adjustments for automated deposition based on simulation of the manufacturing process, machine characteristics and materials. It can help develop high quality composite products by automating the creation of data and documentation.

Analysis

Analysis

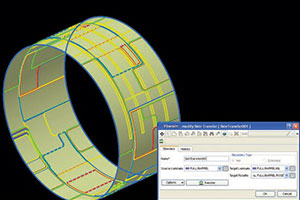

For analysts, Fibersim facilitates composite product optimization by enabling bi‐directional communication between disciplines. The software allows analysts to communicate the desired fiber orientations to the design and manufacturing engineers and provides feedback to the analyst, including achievable fiber orientations based on the material and process.

Case Studies

Fibersim Tutorials

Have Questions?

We Can Help! Contact Us Below: