Optimize Every Phase of the Product Development Lifecycle With Saratech’s CAD Design Services

Get Started With a Quote

Our CAD Design Services Capabilities

CAD design projects seldom follow a consistent timeline. Often, design teams will have a large influx of work that makes resource allocation difficult. By bringing in outside experts, organizations can fill resource gaps and keep projects on track.

Qualified CAD design service providers will have engineers, CAD technicians and modeling experts who can assist with product development, improvements, analysis and prototyping. These professionals will have experience delivering services for a variety of customers, and can help troubleshoot problems to ensure successful project outcomes.

Saratech’s CAD design services optimize every phase of the product development lifecycle through extensive design and engineering expertise. Our design team delivers highly accurate 2-D drafting and 3-D modeling as well as conversion of designs from older software. Each project is managed using a proven methodology that ensures requirements and budgetary targets are met.

Saratech's Area of Expertise

Design

CAD design services help organizations take ideas from concept to final product. By offloading engineering design works, organizations can save money, reduce lead times and allow in-house product development teams to focus on other business requirements. Our engineers have the experience to drive any project to successful completion.

Modeling and Drawing

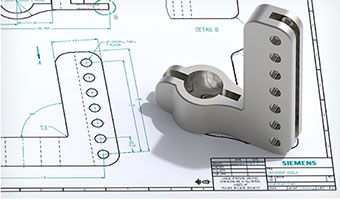

Many design teams are adopting a model-based definition, using 3-D models that incorporate engineering information and other product details. Saratech provides 3-D modeling services as well as traditional 2-D drawings. We utilize the Siemens Teamcenter PLM tool for configuration control, review and signoff.

Reverse Engineering

Reverse engineering refers to the analysis of an existing part to capture dimensions for the development of a 3-D CAD model. Modern 3-D scanning tools allow designers to collect millions of data points with far less effort. Saratech’s design experts then use sophisticated CAD software to develop a highly accurate 3-D model.

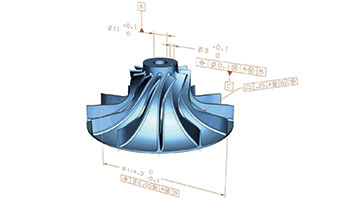

Geometric Dimensioning and Tolerancing (GD&T)

Variations in manufacturing processes cause product parts to differ in dimension from the original CAD model. GD&T is a highly accurate method of measuring allowable variations with product assemblies. Saratech’s GD&T services enable engineers to understand how a part will behave within the assembly and provide the data manufacturers need to control variations.

Complex Surface Modeling

Surface modeling allows the creation of geometries and shapes that might not be possible using traditional methods. It also enables designers to edit existing models and repair third-party parts. Saratech uses sophisticated tools to transform sketches into complex surface models.

Model Checking

Today’s CAD tools enable engineers to check models for compliance with company standards and design guidelines. However, model checking often falls to a design manager who must verify the work of multiple product developers. Saratech offers these services to maximize CAD data quality while accelerating the design cycle.

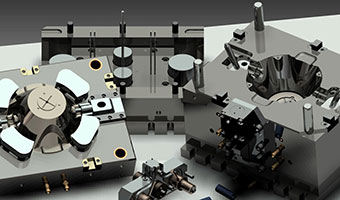

Gauge and Fixturing

Lightweight yet highly accurate gauges and fixtures can be developed using CAD design tools. Saratech applies GD&T techniques to design gauges and fixturing that meet the stringent requirements of aerospace, automotive and other industries. We also leverage our knowledge and experience to evaluate existing gauges and fixturing.

Industries We Serve

Aerospace

Highly accurate 3-D CAD designs for sheet metal design, fiber- and composite part simulations, and more.

Automotive

Complex modeling and composite designs along with 3-D scanning, reverse engineering and legacy design conversion.

Shipbuilding

Calculations and simulations to create viable designs that are transformed into prototypes and final sheet metal components.

Energy, Process and Plant

Detailed 2-D drawings and 3-D models for mechanical equipment, process layouts and plant systems.

Mold, Tool and Die

Design of new products or reverse engineering of tools and dies to reduce costs and lead times and improve quality.

Engineering and Manufacturing

Simulation services to aid in the evaluation and testing of designs, materials and manufacturing processes.

Multiple CAD Package Options Available

The Saratech team has expertise in multiple CAD packages, giving customers convenience and choice in the completion of design and modeling projects. Saratech specializes in Siemens CAD/CAM/CAE products, including NX and Solid Edge, but also utilizes CATIA, SOLIDWORKS and Creo to meet specific requirements.

In addition to providing CAD design services, Saratech sells and supports engineering software for conceptual, design, simulation and manufacturing applications. Our online and customized training programs allow customers to boost productivity through the development of in-house personnel.

Why Choose Saratech?

Disciplined Approach

Saratech takes a highly disciplined approach to every CAD design project. We begin by gathering all relevant formatting and configuration data, and establishing a project plan and timeline with formal change management processes.

Effective Communication

We believe in frequent communications with the customer. The customer’s design team can clearly see what we have accomplished, what we are working on and what remains to be completed. This enables them to report effectively to their customer or internal leadership.

Cost-Effective Service

Our CAD design services are also very cost-effective. We focus on being lean to minimize costs while delivering the very highest levels of quality and discipline. We approach each project with efficiency in mind, identifying the appropriate resources and predecessors for each task.

Resources

Whitepaper: What to Look for in Your Service Provider Read the following whitepaper to gain critical insight into what to look for in your service provider.

E-book: Reduce Wasted Time in CAD Design Discover how improving design data management maturity, enabled by PDM and PLM solutions, helps reduce non-value added time and increase engineering productivity.