Get Simcenter Femap for Your Business!

Simcenter Femap: High Performance Finite Element Modeling Solution

Simcenter™ Femap™ is the world’s leading pre- and post- processor for advanced engineering for finite element analysis. The use of Simcenter Femap helps eliminate expensive prototyping. Femap’s powerful capabilities include high performance FEA modeling, powerful graphics results visualization and evaluation for streamlining your production process. Use Simcenter Femap to create, edit, and import/re-use mesh-centric finite element analysis models of complex products or systems at a low cost. Femap provides easy to use methods for modeling components, assemblies and systems. Femap also helps determine the behavioral response of your design for a given operating environment.

Benefits of Simcenter Femap

- Femap clearly models entity visualization and selection

- Femap streamlines workflows and re-use of previous data definitions

- Femap improves robustness for analysis applications

Introducing Simcenter Femap 2022.2

Simcenter Femap software is now released on a biannual schedule, which began with version Simcenter Femap 2019.1 and continues with version 2022.2. The software is now referred to as Simcenter Femap to reflect that it is a part of the Simcenter portfolio of Siemens CAE products.

Simcenter FEMAP Capabilities

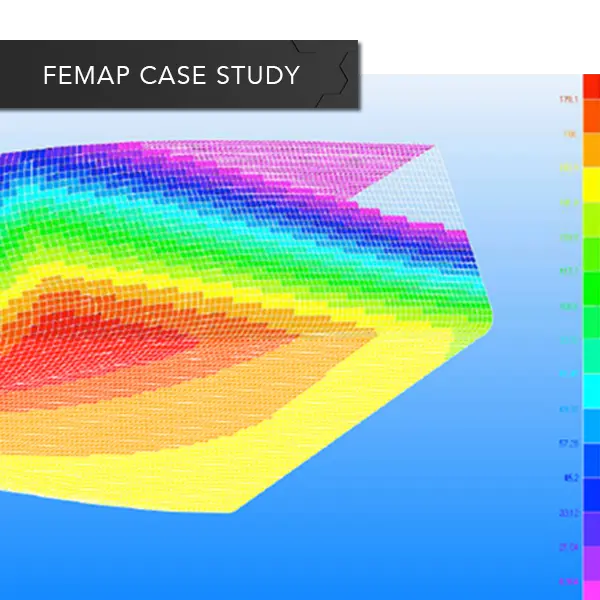

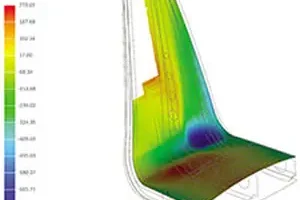

SIMCENTER FEMAP & COMPOSITES

Simcenter Femap is the clear leader of composites analysis through Femap’s continuous development of material models and element types. Femap provides a seamless connection to composites design, accurate solvers, and comprehensive post-processing. This gives Femap the ability to speed up the entire process for simulating laminate composite materials. Composites are highly desirable to manufacturers for their light-weight yet robust qualities. However, because producing prototypes made from composites are prohibitively expensive, Simcenter Femap plays a vital role in the development of new products using laminate composite material.

SIMCENTER FEMAP & FLUID DYNAMICS

Simcenter Femap eliminates approximation and obtains an accuracy of real-world performance for your prototypes. It accounts for all of the physics that influence the behavior of your product, including interaction with fluids, either gases, liquids, or a combination of both. The resilience of your product depends on how they withstand various fluid influences and how your product can turn that influence into an advantage. Simcenter provides industry-leading computational fluid dynamics software in Simcenter Femap that allows you to simulate almost any engineering problem that involves the fluids, structures, and all of the associated physics.

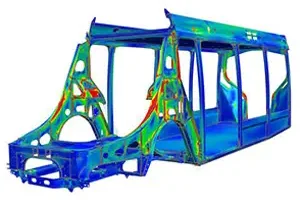

SIMCENTER FEMAP & STRUCTURAL SIMULATION

Simcenter Femap helps determine whether a structure will fail under a prescribed load serves as a significant example for how a component or product assembly reacts under stress or vibration. Understanding these types of cases is necessary for any industry, but as products and materials become more complex, engineers need tools that go beyond linear statics analyses. Simcenter includes the structural solutions you need for a wide range of structural analysis problems within a single user environment. You no longer need one tool for linear statics, another to study fatigue, and yet another for nonlinear analysis. As a result, engineering departments can consolidate analysis tools, and you only need to know a single user interface.

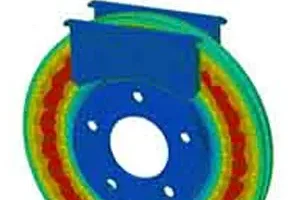

SIMCENTER FEMAP & THERMAL SIMULATION

Simcenter Femap helps provide understanding of your product's performance under thermal stressors can help you design safer, more dependable, and better-performing products. Thermal management is a significant consideration for a wide range of products, including industrial machinery, automobiles, and consumer electronics. The objective of any thermal management solution is to maintain a product’s temperature within a range that is optimal for performance. Accomplishing this may require the removal or addition of heat, either passively or in an actively managed fashion, and this can be evaluated using thermal simulation software. Simcenter places comprehensive, best-in-class thermal simulation capabilities at your fingertips and can help you understand the thermal characteristics of your product and subsequently tailor your thermal management solution for optimal performance.

SIMCENTER FEMAP & MESHING

Simcenter Femap efficiently meshes your models using extensive modeling functions for automatic and manual mesh generation of 1D, 2D, and 3D elements in addition to numerous techniques for the application of loads and boundary conditions. User-defined geometry edits, mesh, and boundary conditions are all associated with the base design, which means when the base design geometry changes, you can rapidly update your model. This approach dramatically reduces downstream modeling time, which results in substantial time savings across a project’s many design-analysis iterations.

SIMCENTER FEMAP & OPTIMIZATION

Simcenter Femap reduces component weight or find the right combination of parameters to improve product performance through comprehensive topology, geometry, and parameter optimization capabilities. Simcenter delivers engineering optimization techniques that can help you systematically search for the best design that satisfies specific criteria.

SIMCENTER FEMAP & PRE/POSTPROCESSING

Simcenter Femap streamlines your production process, giving you more time to evaluate results. Quickly move from multi-CAD geometry data to a complete, run-ready analysis model using unique tools for CAE geometry editing, comprehensive meshing, FE assembly management, multi-CAE solver environments, and fast simulation results post-processing and reporting.

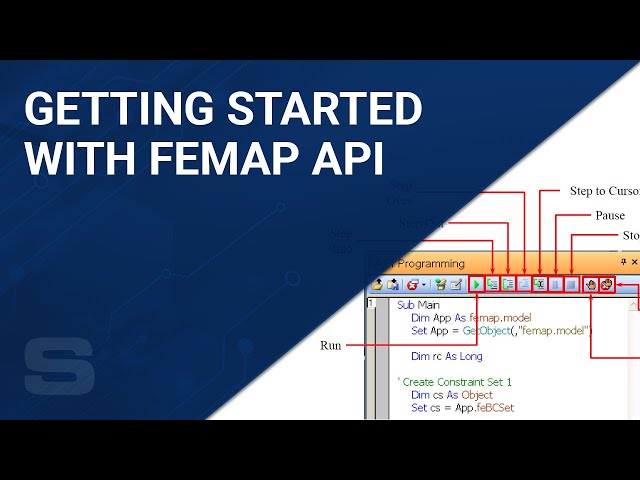

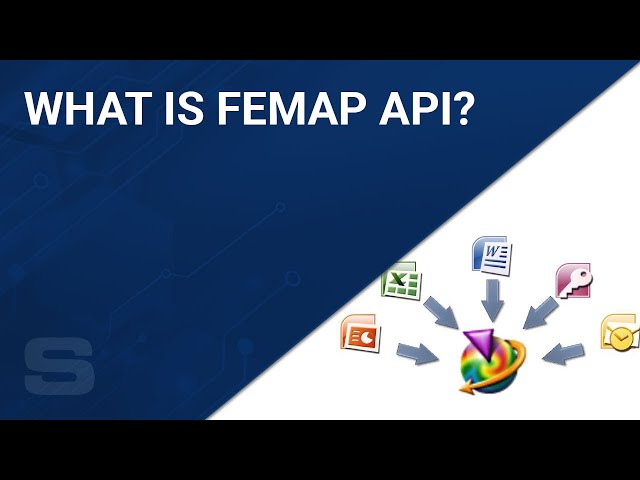

SIMCENTER FEMAP SIMULATION AUTOMATION & SCALABILITY

Are you looking for ways to increase simulation throughput and speed up your analysis process for breakthrough productivity? Learn how by capturing repetitive CAE processes, standardizing them, and then automating them. Simcenter allows you to achieve the expertise of senior analysts and make it available for junior engineers in your organization to use in the form of wizards or templates.

Case Studies

AEROSPACE & DEFENSE

Discover how Femap plays a critical role in the design of NASA's new Orion spacecraft.

MARINE

The ease of customizing Femap enables Bureau Veritas to keep its ship hull verification tool up-to-date with the latest versions of international rules.