Our FEA Consulting Services

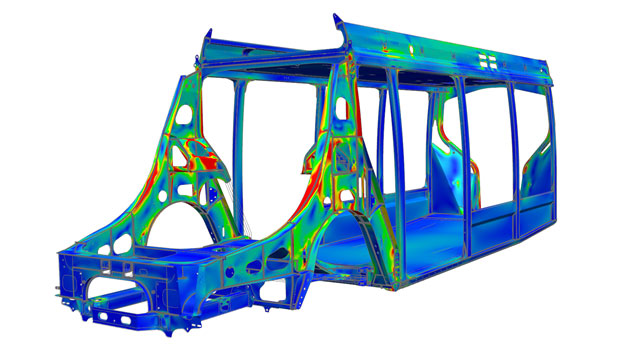

Demand for Finite Element Analysis (FEA) consulting engineers and Computer-Aided Engineering (CAE) services has grown exponentially as the industry and its technology becomes more powerful and sophisticated. With the advancement and improvement of computing tools, companies and engineers can now use advanced software to more precisely forecast how products will react under varying physical conditions.

Coming a long way from its aerospace roots, FEA has now been adopted in many industries. These include electronics, automotive, machinery, medical devices and consumer products. FEA allows companies the ability to test and simulate product designs and digitally develop virtual prototypes. This provides many more degrees of freedom and possibility that developers can use when identifying potential design issues or troubleshooting problems with existing products.

Saratech’s FEA consulting services help manufacturers with the vital step of performance analysis prior to product tooling decisions and manufacturing. Saratech’s FEA engineers have worked for years in helping develop FEA and CAE models and helping customers make better and more informed decisions with the data. This has saved customers money and improved the speed to market for their products.

What Are FEA Consulting Services

Companies who work with Saratech and our FEA engineers will have a team that guides them along the complete FEA and CAE analysis process.

Saratech’s FEA consultants will start with a 3D CAD model of the product or component, the material properties and the load conditions. When starting the analysis, our team will work with you to make sure we identify what information and test are the most important to ensure the analysis model can be simplified and effective.

Through the process and at its end, the FEA engineers will report its findings and offer recommendations, suggestions and best practices for the product or component.

The Value of FEA Consulting Services

FEA helps lower costs and greatly improve the performance of your products and systems. It negates the heavy resource needed for building and testing physical prototypes. FEA allows for greater flexibility and savings, but the process can be complex. It requires experienced FEA engineers who can use the appropriate tools to acquire relevant data and the experience to analyze the data. FEA engineers will be able to establish the right assumptions in order to correctly navigate the analysis so that all primary concerns are addressed.

Having an experienced FEA consultant team helps companies and designers make better and faster product development decisions. This helps tackle complex engineering problems, validate component designs and evaluate performance in different operating conditions.

Saratech's Area of Expertise

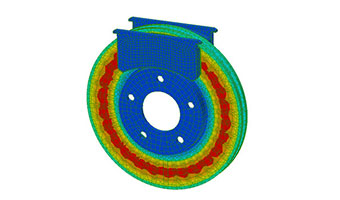

Structural Analysis

Structural Analysis tests the stress placed on a component and evaluates the potential for deformation or fracture under varying operational conditions. This allows designers and engineers to determine the safety of the component when withstanding forces acting against it.

Multibody Dynamics

Multibody dynamics predicts motions and displacement by calculating loads on various parts of a system. This helps determine what would happen if a part works to potentially break or if a mechanism will work as originally designed.

Dynamic and Vibrational Analysis

Dynamic and vibrational analysis determines the shape of structures at different resonant frequencies by computing the resonant frequencies of a structure. This helps product engineers better predict the behavior of a system, allowing product engineers to go beyond traditional static analysis.

Thermal Analysis

Thermal Analysis helps product engineers who need to reduce the risk of failure to thermal stress. Thermal analysis provides an understanding of heat loads and temperature destruction by using the transfer of heat in a component through convection, conduction and radiation.

Why Choose Saratech?

Full Spectrum Service

Saratech offers the entire spectrum of FEA and CAE consulting services, from conceptual design to detailed analysis to testing and even manufacturing. We coordinate all aspects of the project, freeing our customers to focus on product development.

Time and Cost Effective

Our team is very schedule-driven, ensuring that every project is completed on time and within budget. Our engineers have extensive expertise in FEA and CAE tools, enabling us to identify potential problems and deliver actionable information.

Resources

Whitepaper: What to Look for in Your Service Provider Read the following whitepaper to gain critical insight into what to look for in your service provider.

Whitepaper: Improving Your Company's Simulation Capabilities and Processes for Business BenefitThis whitepaper introduces a general framework used to address the top simulation issues companies experience.