Overview

The possibilities are endless when it comes to 3D printing. Whether on land, sea, over even Mars - designers are finding new innovative ways to help make our world a better place. Discover the amazing parts people are creating with 3D printers.

3D Printing Solutions

Saratech offers sales, service, and support of Markforged, and BigRep 3D printers. The breadth of 3D Printing technologies allows us to provide the right solutions according to customer requirements.

Find the Right Solution for Your Needs. Connect With a Saratech Expert Today.

Reaching New Heights

Björn Lindwall, the CEO and founder of SolidEngineer in Sweden, scaled Mount Everest with Markforged printed parts! As a Markforged partner, SolidEngineer had access to several Markforged printers, making the task of designing, prototyping, and fabricating the end-use parts far more simple. For the satellite communication boxes, the team had to create a housing that could withstand the freezing -40 C temperatures and high altitudes of Mount Everest, as well as the multiple hits it would take while being pulled up the mountain. The box was fabricated out of Onyx, a carbon fiber filled nylon material that can retain a decent amount of strength at low temperatures. To document these climbs, he created bjornadventure, a project and website set up by Björn that now also investigates how additive manufacturing technology can be used in mountaineering and other adventure activities.

Image Source: BANDD Designs/ICON/New Story

Creating Homes and Habitats

Imagine building a home in one day. With the additive manufacturing technology of today, tiny homes can be 3D printed in just 24 hours! New Story, a housing non-profit company in San Francisco, partnered with construction technology company Icon, and used 3D printing to produce a 350-square-foot tiny home in 48 hours for $10,000. Projections for 600- to-800-square foot homes based on this prototype are looking to come in under $4,000 with a build time of just 24 hours. These fast, affordable homes are designed for use in diverse locations — from providing economical housing in Texas, all the way to rough climates and terrains in El Salvador.

Now, imagine the same rapid housing concept in space! A 3D Printed Habitat Challenge, launched by NASA, drives innovation in technologies needed to autonomously 3D print habitats with indigenous resources and recyclable materials on the moon, Mars, and other planets.

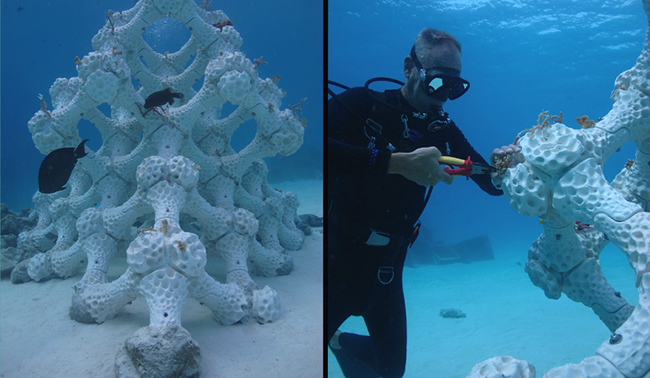

Image Source: Alex Goad, Reef Design Lab

Saving Ecosystems

The continuous rise of ocean water temperatures creates an unsuitable environment for coral reefs that support an abundance of sea life. Researchers are turning to 3D printing for a solution to the endangered ecosystems. By 3D printing “new” coral reefs, engineers can recreate complex coral shapes in a way that is inviting to sea life. While addressing the climate crisis is the only way to truly fix the problem in the long term, engineers have developed many fantastic designs to help mitigate the problem temporarily.

Printing Living Tissue

In the medical field, researchers are developing 3D printing systems that print living tissue to treat deep wounds and severe burns. Scientists from the University of Toronto and Sunnybrook Research Institute have created a handheld 3D bioprinter that prints skin cells to treat burn victims. A team at Wake Forest School of Medicine has also developed a 3D printer that uses skin cells instead of ink, layering new healthy skin over damaged skin.

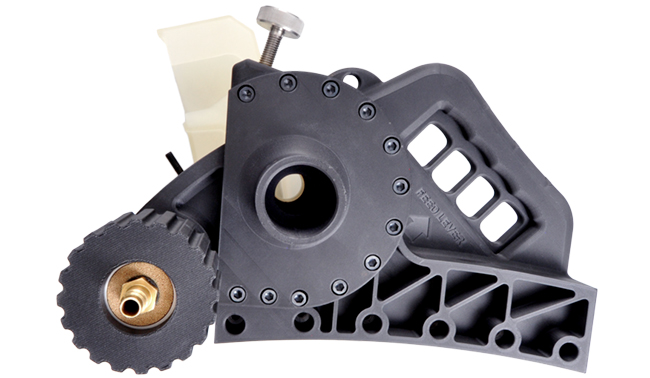

Image Source: Siemens Gas & Power

Industrial Tooling

Using Markforged 3D printers Industrial Series 3D printers and continuous carbon fiber material, Siemens Gas & Power created a 3D printed customized circular cutting saw — and only needed to purchase the motor and blade. The Gas & Power division owns compressors, generators, and turbines around the world. Often, the gas turbine housings need maintenance, so engineers need to use a circular saw to repair them. Standard cutting saws aren’t contoured, meaning the team used to send all the components overseas, wait for the custom plate to be made, and then reassemble the tool when they received the parts back. By using 3D printed components, the team saved roughly $8,000 per tool (of which there are many), and reduced lead time by 35 days. Now, their engineers can efficiently repair turbines in the field instead of waiting on third parties.

What Will You 3D Print?

The list of applications for additive manufacturing goes on and on for countless industries using a variety of printing materials. Think dentistry, eyewear, prosthetics, furniture design, archaeology, paleontology, and forensic sciences, to name just a few. You can be sure that 3D printing will continue to be used to spark creativity and improve our world around us.