An Introduction to Markforged Simulation Software

Blog Article | September 1, 2023

Additive manufacturing enables organizations to produce parts on demand, alleviating delays due to supply chain constraints. 3D printing cuts lead times from months to weeks or even days and can reduce costs as well. It is especially valuable for replacing parts that have been discontinued.

However, transitioning to 3D printing from legacy processes often presents a challenge. In order to validate the replacement part’s strength and performance, organizations must print and test it manually. Multiple design iterations are often needed, lengthening lead times, wasting materials and negating many of the benefits of 3D printing.

There are a number of part validation tools on the market, but they tend to be of limited value with additive manufacturing. These tools weren’t designed to handle the many variables associated with 3D printing, such as infill geometries and layer heights. Without proper validation, manufacturers sometimes resort to overbuilding the part with excessive infill or reinforcement or stick with legacy methods for producing load-bearing parts.

Markforged Simulation overcomes these obstacles by enabling the virtual validation of parts. Simulation helps organizations take full advantage of Markforged 3D printing technology to produce parts for demanding production use cases.

About Markforged Simulation

Introduced in November 2022, Markforged Simulation is the result of the company’s acquisition of Teton Simulation. Markforged based its simulation software on the Teton product and integrated it into its Eiger software.

It is included in the Advanced Digital Forge Subscription tier and accessed through the Eiger cloud software platform. It currently works for parts printed with the Markforged Onyx filament alone or Onyx reinforced with carbon fiber using any Markforged 3D printer, and 17-4PH Stainless Steel v2 on the Metal X. In future updates, Markforged will include compatibility with other materials.

Benefits of Markforged Simulation

Simulation enables the virtual validation of parts from within Eiger as part of the slice and print workflow. Because it is cloud-based and accessed on a subscription basis, Simulation doesn’t require investments in costly validation tools or onsite hardware.

Parts can be validated by entering a few parameters and clicking a few buttons, eliminating the need for time-consuming analysis by experts. Simulation even takes the guesswork out of print configurations, enabling the optimization of settings to improve strength, reduce material costs or shorten print time.

With Simulation, there’s no need for multiple design-print-test-iterations or overbuilding parts. Designers can optimize the part for the specific application and know before printing that it will meet performance requirements. Organizations can save hundreds or thousands of dollars per part in labor and material costs while gaining faster delivery of trusted parts.

Designers also gain the confidence to use thermoplastic and fiber-reinforced parts in applications that would traditionally require metal. This enables organizations to maximize the benefits of additive manufacturing.

How Markforged Simulation Works

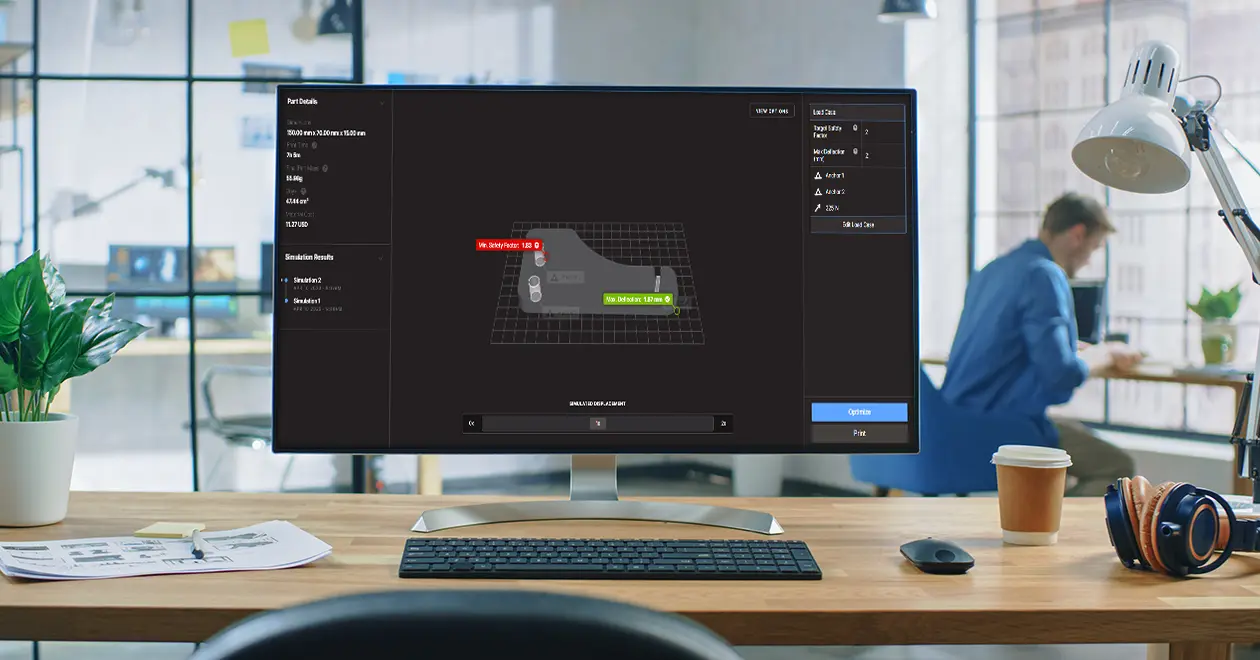

Designers can access Simulation from within Eiger before printing a part that has been sliced. Selecting the Simulation button in the upper right corner of the view screen will take the user to the Simulation Configuration tool.

SETTING UP THE LOAD CASE

The user sets up a Load Case by selecting one or more Loads and Anchors. A Load is the surface of the part that’s subjected to external force, and an Anchor is the portion of the part that’s restricted from moving. Loads and Anchors can be created quickly with simple point-and-click selections. The user can set the amount of total force by entering the value in Newtons, and choose the direction of the force using the angles tool or floating widget.

Additional parameters include Max Deflection and Target Safety Factor. Max Deflection defines how many millimeters the part should move under load. The Target Safety Factor is a multiple of the expected load that the part should be able to withstand.

VALIDATING THE PART

Once the Load Case is configured, the user simply clicks the Validate button and lets the software do the work. Because Simulation is cloud-based, the user can work on other projects and tasks during the validation process.

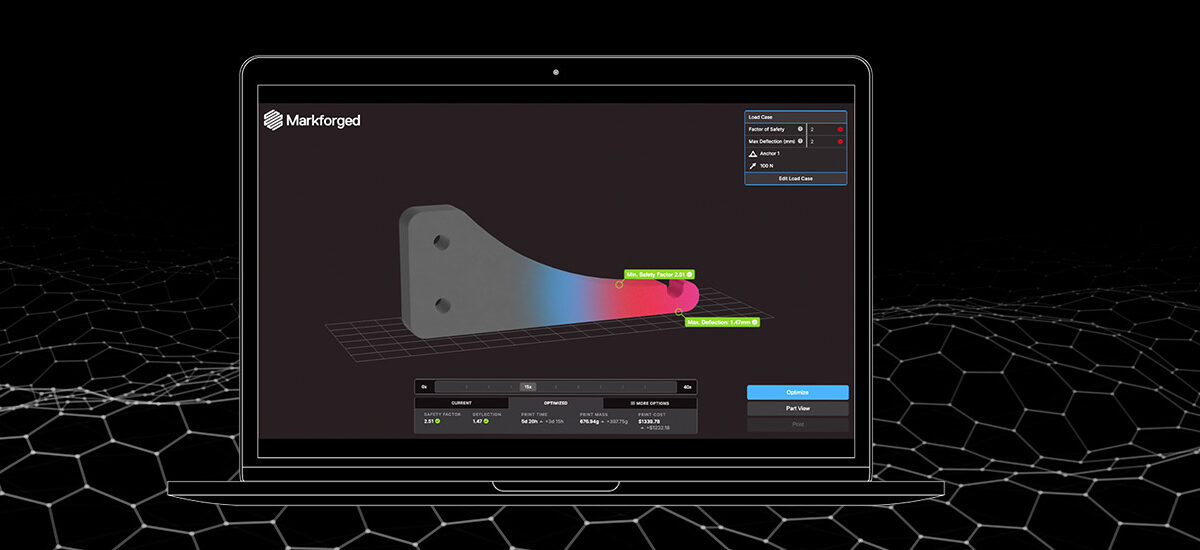

For the first pass, Simulation will determine whether the part meets the defined parameters. The Max Deflection and Max Safety values will be displayed in a green or red box to show whether the part passed or failed. A slider allows the user to exaggerate the part’s displacement as an aid in visualizing deflection.

In the Print Optimization step, the user will be able to review various options for adjusting the part configuration according to the Load Case requirements.

OPTIMIZING PRINTING

Even if the part design meets all the Load Case parameters, it may be possible to improve it by changing print settings. The Print Optimization feature reviews the part in terms of strength, material usage, print time and other factors, and adjusts infill, wall, floor and reinforcement levels. The user is provided with multiple options for optimizing the printing process based on one or more of these factors. The More Options button enables the user to compare the various options.

Once the part configuration and print settings are selected, the user selects Apply Optimization. Eiger will re-slice the part and get it ready to print.

Why Saratech Recommends Markforged Simulation

Markforged Simulation uniquely fills a need in additive manufacturing. This easy-to-use software dramatically reduces the time and cost associated with the design-print-test process. It also eliminates the need to validate parts using legacy tools and techniques. It assures the designer that the part will meet the requirements of the use case and optimizes the printing process and material use. Organizations can take advantage of trusted parts faster and maximize the value of their 3D printing investments.