WELCOME TO THE NEW FX10!

This Markforged next-generation industrial composite 3D printer is even faster!

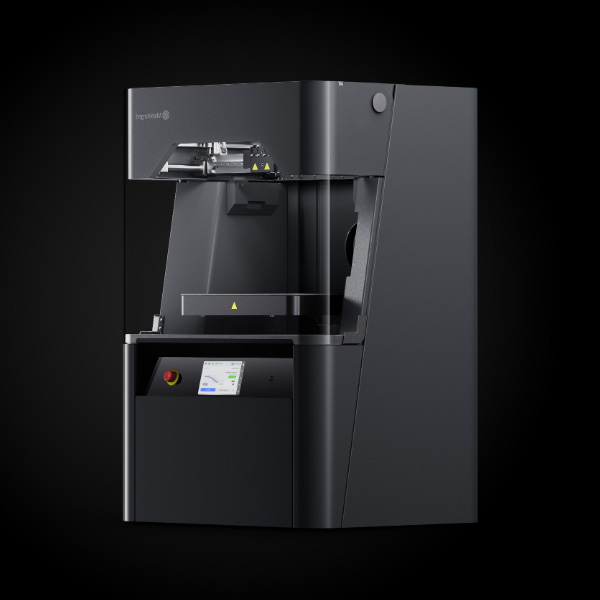

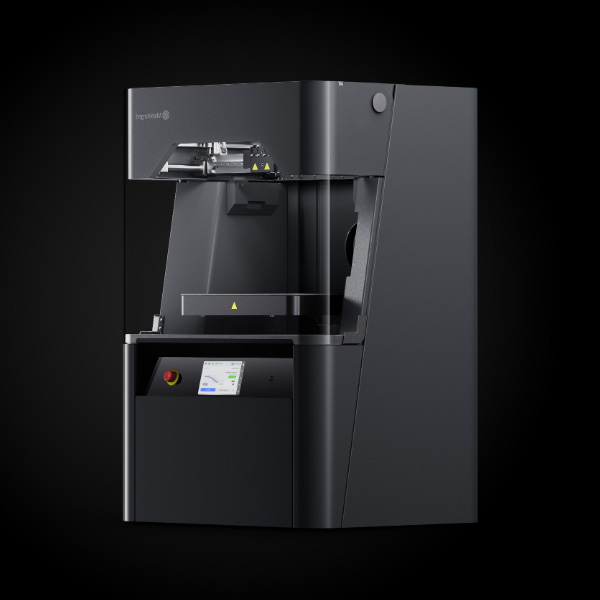

Introducing Markforged FX10

Blog Article | November 7, 2023

The future of Markforged is here with the new FX10. Built on the same principles of the Markforged X7, this next-generation industrial composite 3D printer is even faster and easier to use while delivering strong, accurate parts on every print.

Markforged 3D Printers & 3D Printing Capabilities

Markforged changes what you know about a 3D printer and metal printing. Markforged 3D printers transcend the realm of 3D printer prototyping and trinkets. Find the right Markforged 3D printing solution for your needs!

What Is the FX10

With a new modular architecture, the FX10 boasts a fresh design built for effortless upgrades. It also incorporates printhead-mounted optical sensors to confirm precision of components and evaluate the overall functionality of the device.

While utilizing automatic calibration and material changeover, the FX10 provides a user-friendly experience that requires minimal intervention, reducing the necessity of operators.

Key Features

Modular Print System

Sturdy and adaptable machine framework crafted to deliver immediate and long-term value

Print-Head Mounted Optical Sensors

Unmatched visibility into the quality of components and printer health

FX10 Prints Large, High-Quality Parts Quickly

More automated and easy to use all while using premium hardware

Value

Boost manufacturing profitability and enhance productivity by:

- Shrinking part costs up to 90% and lead times from months to days

-

Increasing output efficiency while reducing operational expenses

-

Minimizing tangible inventory

-

Sustaining continuous operation of your manufacturing lines with on-demand spare parts

FX10 Specifications

- Heated build chamber reaching up to 60 degrees Celsius

- High-speed printing of composites with Turbo Mode (twice as fast as X7!)

- Build volume of 375mm x 300mm x 300mm

- Vacuum-sealed print bed with reusable print sheets

- A material drawer contains built-in, individually sealed storage bays for up to four 800cc spools

- Automated machine and pre-print calibration