Markforged X7 3D Printer Industrial Series

Designed from the ground up to survive the production floor environment, the Markforged X7 3D printer (from Markforged's Industrial Series) can print parts stronger than machined aluminum for a fraction of the cost. Produce industrial-grade manufacturing jigs, jaws, tools, fixtures, and end-use parts with breakthrough quality and precision. The Markforged X7 3D printer delivers unparalleled surface finish, build size, and reliability.

Build Volume: 330 mm x 270 mm x 200 mm

Layer Height: 50 to 250 μm

Technology: Fused Filament Fabrication (FFF) & Continuous Fiber Fabrication (CFF)

Connect With a Saratech Expert Today to Get Started.

The Markforged X7 3D Printer Just Got Faster!

Introducing Turbo Print for the Gen 2 Markforged X7 3D printer. With Turbo Print, you can print Onyx parts at twice the speed of a standard Markforged X7 3D printer. The quicker you can produce parts, the faster you are achieving ROI.

Users can expect:

- Faster lead times

- Become more agile in manufacturing operations

- Reduce development time and line downtime

Start accepting more print jobs and achieve twice the amount of production! Print at 250 um, and of course, Turbo printed parts will maintain Markforged's unbeatable surface finish.

Markforged Metal X7 3D Printer Capabilities

With the same all-aluminum unibody construction with a build volume of 330 x 270 x 200mm, the X7 appears to be not unlike the X3 or X5; however, the difference is in the print materials. The X7 offers users the ability to print not only with Onyx and fiberglass but also HSHT fiberglass (high-strength, high-temp fiberglass), carbon fiber, and Kevlar.If you have projects that require multiple types of printing materials, then Markforged's X7 is the ideal 3D printer for you. As a 3D printer capable of printing with the most diverse set of materials, the X7 is the flagship of the Industrial Series.

Markforged Metal X7 3D Printer Features

The X7 delivers the strength you need for tooling and functional parts. Cut costs and eliminate effort with this industrial printer designed for accuracy and built to survive the production floor environment. The standard options available for the X3 and X5 are also available for the X7. Cloud-connected software and a 4.3” touchscreen come standard with every Markforged printer. With automatic version control, real-time fleet management, and cloud-based collaboration, Markforged's own 3D printing software, Eiger, is one of the best software platforms of its type on the market. Additionally, laser bed leveling is supplied, allowing precision to just 1 micron in the z-axis, and an advanced sensor suite provides unparalleled reliability. Add to that an ultra-flat gantry system and a machined aluminum stage with kinematic bed coupling, the incredibly versatile X7 delivers unmatched performance. With the Gen 2 X7's Turbo Print mode, you can print Onyx parts at twice the speed of a standard Markforged X7. The quicker you can produce parts, the faster you are achieving ROI.

Plastic Compatibility

ONYX FILAMENT

Designed to combine the toughness and durability of Nylon with the dimensional stability and strength of composites, Onyx is the world's most capable 3D plastic.

ONYX ESD

Onyx ESD is a static-dissipative chopped carbon fiber nylon material, precision-engineered for a tight range of surface resistance. Onyx ESD meets ESD-safe requirements while offering the same industry-leading print quality of Onyx.

ONYX FR

Fiberglass reinforced Onyx composites are as strong as metal and 20x stiffer than typical 3D printed parts. Onyx FR should be used to print parts that require high-strength, low-weight, and flame-retardant properties.

NYLON

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

PRECISE PLA

Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable.

SMOOTH TPU 95A

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

Continuous Fiber Compatibility

CARBON FIBER

The strongest and stiffest fiber with the highest strength-to-weight ratio. Carbon fiber filament can replace aluminum at half the weight. Utilize this material when you want exceptional stiffness and minimal deflection.

FIBERGLASS

Fiberglass is the perfect entry-level fiber for 3D printing. It's low cost and 26x more rigid than nylon. Print parts that are an order of magnitude stiffer than typical 3D printed objects and produce functional prototypes, fixtures, jigs, and much more.

KEVLAR

As stiff as fiberglass and much more malleable, Kevlar possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. An excellent option for a wide range of applications such as end effectors, cradles, soft jaws, and end-use parts.

HSHT FIBERGLASS

With the highest impact resistance and a flexural strength only second to carbon fiber, HSHT Fiberglass is ideal for applications requiring high heat resistance such as welding fixtures or thermoset molds.

Additive Manufacturing Savings

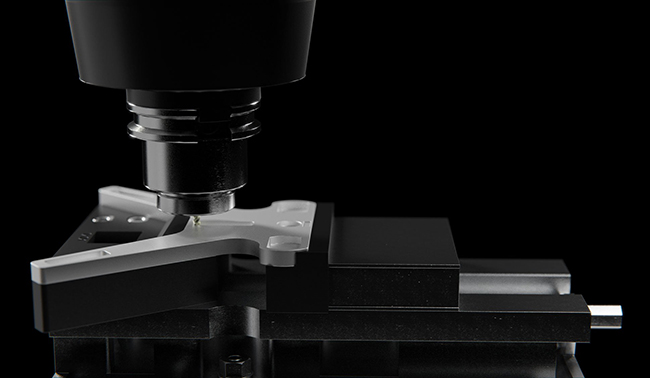

End Effectors

Keep your production line running at full speed. Reduce lead time and cost on end effectors by printing on-site same day tooling. Print new tools and functional replacements for old parts. Save time and money with carbon fiber 3D printing.

Typical Machined Cost: $ 285.61

Markforged 3D Printed Cost: $ 9.45

Savings: 97%

Soft Jaws

Use your CNC resources for only the most critical machining operations. Increase machining bandwidth by 3D printing composite-reinforced soft jaws and custom work-holding tools with the strength necessary for heavy duty machining operations.

Typical Machined Cost: $ 721.70

Markforged 3D Printed Cost: $ 116.04

Savings: 84%