Are You Maximizing Your Teamcenter PLM Potential?

Get the most out of your PLM solution to better manage your engineering data and processes.

Upgrading Teamcenter PLM

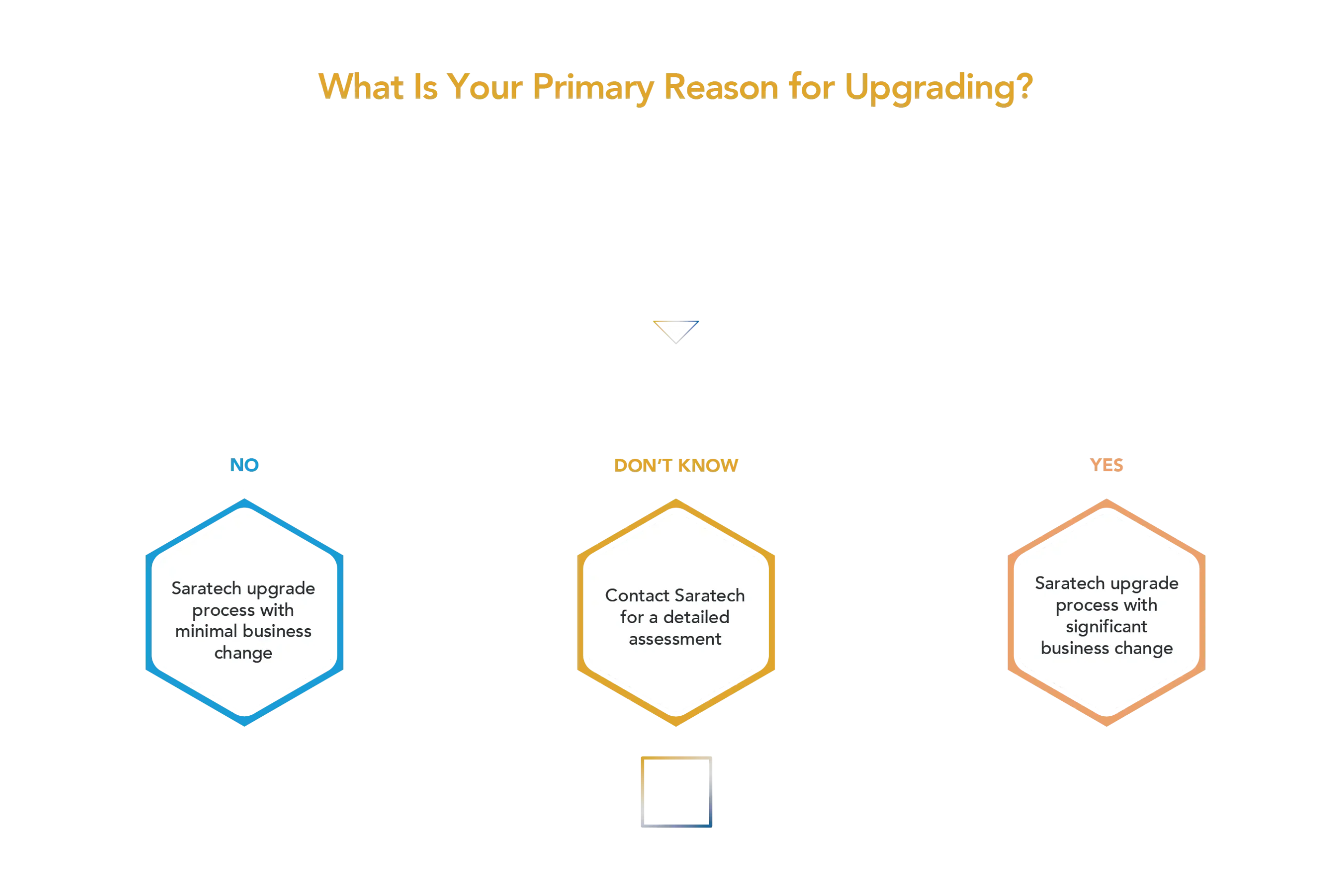

There are many reasons why you may want or need to upgrade your Teamcenter PLM implementation. Once you identify your particular reasons, the next thing to understand is business impact. An upgrade may have significant impacts on your business processes whether you want to them or not. As an example, upgrading from an old, out of support version of Teamcenter to the latest version will almost certainly require some changes to your existing business process.

At Saratech, we use an upgrade approach tailored to the amount of business process change associated with the upgrade.

With minimal business change, we focus on understanding: data migration, interoperability (especially with CAD version) customizations, infrastructure requirements and validation tests.

For upgrades that require significant business process change, we additionally address: business process mapping, configuration planning, to the list above.

Why Saratech Is an Ideal Partner for Your Teamcenter PLM Project

At Saratech we partner with industry-leading software companies to provide our customers with the right solution for their product development needs. Our customers rely on us for world-class design, analysis, manufacturing, data, and process management software recommendations and deployments to stay ahead of the competition. We provide engineering expertise, services, software, and manufacturing solutions to improve your product development experiences. We help optimize engineering processes to accelerate product development and speed up time-to-market. For a successful implementation, Saratech is your ideal partner, providing:

1

Teamcenter Experience

We have been a Siemens Teamcenter PLM partner since our founding in 2008. Over this time, we have completed dozens of successful implementations of Teamcenter PLM, including Teamcenter, Teamcenter Rapid Start, and Teamcenter X, across multiple industries.

2

Technical Proficiency

Our technical experts include architects and PLM engineers who are proficient in configuration, customization, integration with other systems, and data migration.

3

Project Management Skills

All projects include a project manager to track and maintain deliverables, schedule, and budget. The project manager also communicates status via regular customer meetings.

4

Fast Time-to-Value

Our structured implementation process minimizes install and configuration time.

5

Capture of Your Unique Needs

Every company is different, so while we use a standard, structured approach for our Teamcenter implementations, our process accommodates capture and implementation of your business processes/workflows, business scalability needs and plans, and change management maturity.

6

Training and Support Services

We offer Teamcenter training to ensure that your end-users and administrators can use the system effectively. We also have post-launch support, including a standard hyper-care period where we proactively monitor the system for the first week or two after go-live, and we offer longer term help desk support services.

Get the Most Out of Your Teamcenter Implementation Investment, Maximize Benefits, and Realize Full Potential.

To get the most out of your Teamcenter implementation investment and maximize the benefits it can bring to your organization, consider the following best practices:

By following these best practices and tailoring the implementation to your organization's specific needs, you can maximize the return on your Teamcenter investment and realize the full potential of PLM in improving your product development processes and overall business performance.

CLEARLY DEFINE OBJECTIVES

Clearly define your goals and objectives for implementing Teamcenter. Understand what specific challenges you want to address and what outcomes you expect from the PLM system. Having clear objectives will help you focus on the areas that matter most to your organization.

THOROUGHLY ASSESS NEEDS AND REQUIREMENTS

Conduct a comprehensive assessment of your organization's PLM needs and requirements. Involve key stakeholders from different departments to understand their pain points and priorities. This will ensure that the implementation addresses the real needs of the business.

ENGAGE TOP MANAGEMENT SUPPORT

Secure support from top management and involve them in the decision-making process. Having executive buy-in ensures that the implementation receives the necessary resources and attention, and it sets the right tone for driving adoption across the organization.

CHOOSE THE RIGHT TEAM AND PARTNERS

Assemble a skilled and dedicated implementation team that includes experts from both your organization and the PLM vendor. Additionally, choose a reliable and experienced implementation partner, if needed, to guide you through the process.

PROPERLY PLAN AND SEQUENCE

Develop a detailed implementation plan, including a sequence of modules and functionalities to be deployed. Prioritize critical areas and plan a phased approach to implementation, ensuring smoother integration with existing processes and systems.

EFFECTIVE CHANGE MANAGEMENT

Understand that implementing PLM will likely bring changes to existing processes and workflows. Invest in change management efforts to prepare employees for these changes and address any resistance. Training and support are crucial to help users adapt to the new system.

DATA MIGRATION AND QUALITY

Ensure a smooth and accurate data migration from existing systems to Teamcenter. Pay attention to data quality and cleanup to avoid issues caused by inaccurate or redundant data.

PROMOTE USER ADOPTION

Actively promote user adoption and encourage employees to embrace the PLM system. Highlight the benefits of using Teamcenter and provide ongoing training and support to help users fully utilize its capabilities.

CONTINUOUS IMPROVEMENT

Treat Teamcenter implementation as an ongoing journey rather than a one-time project. Continuously review and optimize processes, collect feedback from users, and seek ways to improve the system's performance and functionality.

MEASURE AND TRACK SUCCESS

Establish key performance indicators (KPIs) to measure the success of your Teamcenter implementation. Regularly track these metrics to evaluate the system's impact on your organization's productivity, efficiency, and bottom line.

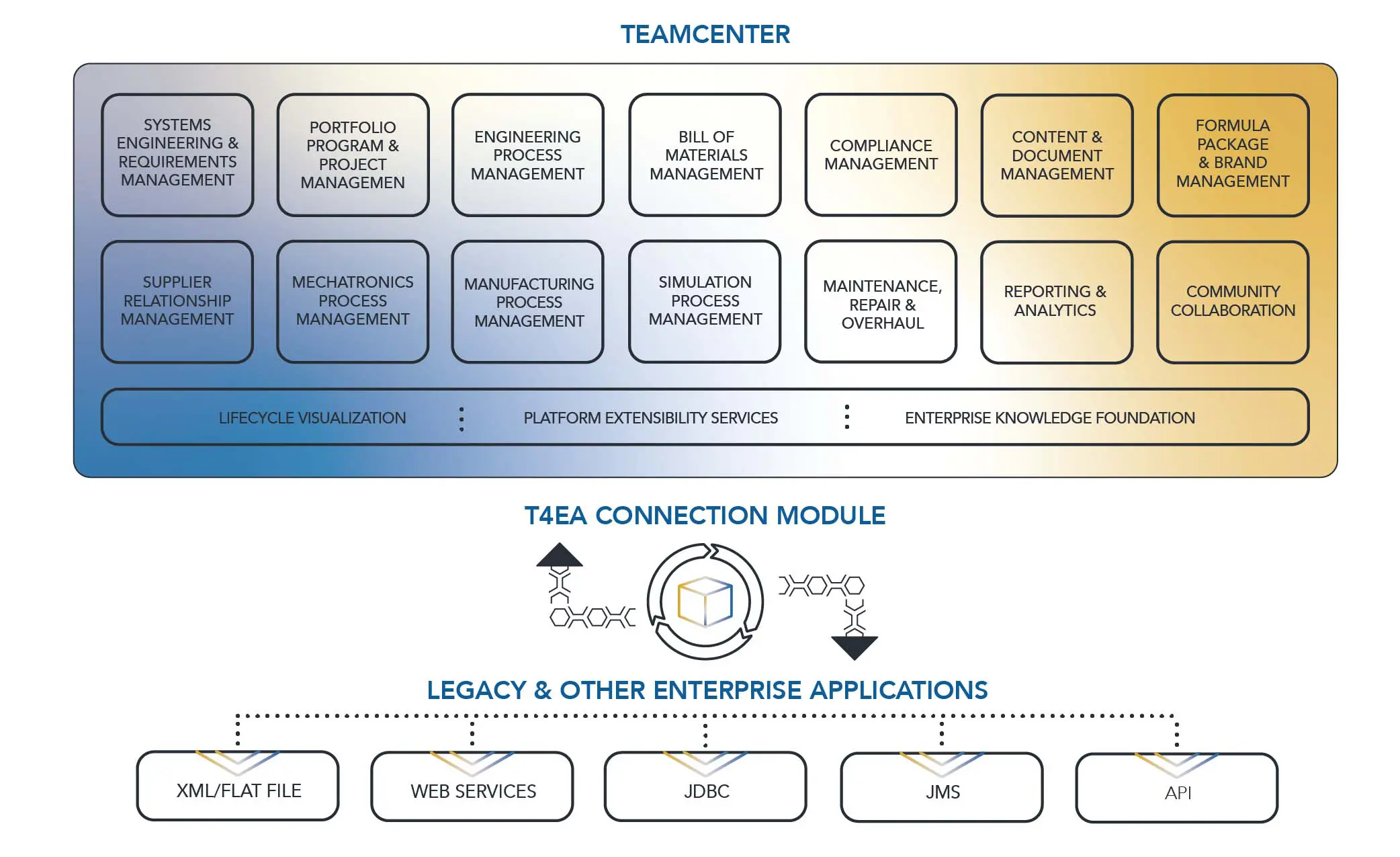

Teamcenter Integration

Teamcenter's integration capabilities enhance its functionality, improve data consistency across different systems, and facilitate seamless collaboration and data exchange between various stakeholders in the product development process. The flexibility and extensibility of Teamcenter's integration capabilities make it a versatile PLM solution for modern enterprises seeking a connected and collaborative approach to product development.

Teamcenter Offers a Robust and Comprehensive Integration Solution to Any External Applications.

Teamcenter has excellent integration potential with various other software applications and systems. Its open architecture and robust APIs (Application Programming Interfaces) allow seamless integration with different tools and technologies.

COMPUTER-AIDED DESIGN (CAD) SOFTWARE

Teamcenter integrates with popular CAD tools like Siemens NX, Solid Edge, AutoCAD, CATIA, Creo, and others. This integration allows users to directly access and manage CAD models and drawings within Teamcenter, ensuring data consistency and version control.

ENTERPRISE RESOURCE PLANNING (ERP) SYSTEMS

Integration with ERP systems like SAP, Oracle, or Microsoft Dynamics allows for synchronized data exchange between PLM and ERP platforms. This helps streamline the transfer of engineering data to support manufacturing and other business processes.

PRODUCT DATA EXCHANGE FORMATS

Teamcenter supports various industry-standard data exchange formats like STEP, JT, IGES, and others, enabling data interoperability with other systems or collaborating with partners using different CAD software.

SIMULATION AND ANALYSIS TOOLS

Teamcenter can integrate with simulation and analysis software, such as ANSYS, Simcenter, and Abaqus, allowing for seamless transfer of simulation data and results.

REQUIREMENTS MANAGEMENT TOOLS

Integration with requirements management tools ensures that product requirements are linked and managed consistently throughout the product development lifecycle.

Manufacturing Execution Systems (MES)

Integrating Teamcenter with MES systems enables the efficient transfer of manufacturing instructions, work orders, and quality data from PLM to the shop floor.

Computer-Aided Manufacturing (CAM) Software

Integration with CAM software enables the transfer of manufacturing process data and CNC (Computer Numerical Control) machine instructions directly from Teamcenter.

Microsoft Office Suite

Teamcenter provides integration with Microsoft Office applications like Word, Excel, and PowerPoint, allowing users to interact with PLM data seamlessly from familiar Office tools.

Supplier Relationship Management (SRM)

Integrating Teamcenter with SRM systems helps streamline supplier collaboration, procurement processes, and supplier performance management.

IoT and IIoT Systems

Integration with Internet of Things (IoT) and Industrial Internet of Things (IIoT) platforms enables the collection of real-time data from connected products and devices, supporting predictive maintenance and improving product performance.

Service Lifecycle Management

Integration with Service Lifecycle Management (SLM) platforms allows for improved management of product service and maintenance data.

Data Migration Process Into Teamcenter

It's essential to thoroughly plan and execute the CAD data migration process to avoid data loss, ensure data integrity, and achieve a successful integration of CAD data into Teamcenter. Collaboration between the migration team, CAD experts, and PLM consultants can significantly contribute to the success of the migration process. Additionally, conducting pilot migrations and testing in a controlled environment before the final migration can help identify and resolve potential issues early on.

The CAD data migration process from an external system to Teamcenter involves several steps to ensure a smooth and accurate transfer of data. Here is an overview of the typical CAD data migration process:

DATA ANALYSIS AND PREPARATION

Identify the CAD data to be migrated, including 3D models, 2D drawings, and associated documents.

Analyze the data structure, file formats, and metadata in the external system.

Prepare the data for migration by cleaning up and organizing it as needed.

Data Mapping

Define a mapping between the data structures and attributes in the external system and the corresponding data structures in Teamcenter.

Ensure that the mapping accurately represents the relationships and properties of the CAD data.

Metadata Extraction

Extract metadata (e.g., part numbers, descriptions, revision history, etc.) from the CAD files and associated documents in the external system.

Transform the extracted metadata into a format compatible with Teamcenter.

File Conversion

Convert the CAD files from the external system into a format compatible with Teamcenter (e.g., JT, NX, or other supported formats).

Ensure that the file conversion maintains data integrity and fidelity.

Data Loading

Load the converted CAD files and associated metadata into Teamcenter.

Create new items or update existing ones based on the data mapping and metadata extracted from the external system.

Data Validation

Perform data validation to ensure that the migrated CAD data in Teamcenter is accurate and consistent.

Conduct sample checks and audits to verify the correctness of the migrated data.

Testing and Verification

Test the migrated CAD data in Teamcenter to ensure that all links, relationships, and references are preserved and functioning correctly.

Verify that CAD assemblies and structures are accurately represented in Teamcenter.

User Training and Acceptance

Provide training to users on how to access and work with the migrated CAD data in Teamcenter.

Obtain user acceptance and feedback to address any issues or concerns.

Final Migration and Go-Live

Perform the final data migration to ensure that the most up-to-date CAD data is transferred to Teamcenter before the system goes live.

Monitor the migration process and address any last-minute issues.

Post-Migration Support

Provide post-migration support to address any challenges or questions that may arise after the CAD data migration.

Outsource Support to Reduce Critical Resource Strain

See our Support section for a model that fits your business. These services can begin right after your system is through go-live and post-launch validation. We will be your help desk offering full support as you need it.

Flexible Training Options

Saratech instructors are seasoned engineering professionals with many years of industry experience and passion to share their expertise.

See our extensive list of training options, both remote and on-site, instructor-led, and at your own pace.