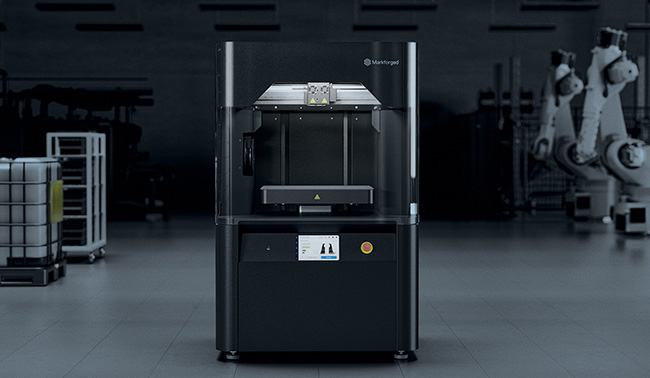

Markforged Industrial Series 3D Printers

These Printers Are the Go-to Solution for Manufacturing Tooling

The Markforged Industrial Series delivers exceptional accuracy, reliability, and repeatability so you can continuously create the parts you need. Save time and money printing high-quality parts previously machined out of aluminum. With laser precision, cloud-connected software, and material tracking, these 3D printers are built for superior performance.

How the Markforged Industrial Series Works

Named for its industrial-grade 3D printing, the Industrial series delivers the strength you need for tooling and functional parts. Cut costs and eliminate effort with 3D devices designed for accuracy and built to survive the production floor environment.

Say goodbye to waiting weeks for parts and start getting them within hours. The Industrial series 3D printing devices are the go-to solution for manufacturing tooling (Jigs, Jaws, Tools, Fixtures). Save time and money printing tools previously machined out of aluminum.

Need Help With a Markforged Industrial Series 3D Printer?

Saratech's 3D printing team is committed to your success. We provide everything you need to get your Markforged Industrial Series 3D printer system up and running, while assisting you in being more productive!

We can also advise you on 3D printing orientation, fiber routing, and guide you in creating and making components stronger or faster.

Connect With a Saratech Expert Today to Get Started.

3D Printers of the Industrial Series

Markforged X3 3D Printer

The Markforged X3 3D printer drives innovation with the ability to print heavy-duty carbon parts that won't bend or break under pressure. This cost-effective 3D plastic printer uses chopped carbon fiber filament reinforcement to create pats ideal for tooling and applications that require real strength.

- Produce carbon parts 20% stronger and 40% stiffer than ABS

- Ultra-precise motor encoders made for speed

- Laser micrometer 3D scanner

Markforged X7 3D Printer

The Markforged X7 3D printer delivers continuous carbon fiber parts that are exceptionally strong, supremely stiff, ultra-lightweight, and incredibly versatile. Parts printed with Onyx and reinforced with carbon fiber filament, fiberglass or Kevlar are ideal for manufacturing equipment, jaws, tooling, and end-use parts.

- Fiber parts stronger than 6061 Aluminum and 40% lighter

- 50x faster and 20x cheaper than machining

- Dual nozzle print system that supports Continuous Carbon Fiber

Markforged FX10 3D Printer

The Markforged FX10 3D printer combines increased size, speed, and automation while upholding a user-friendly interface. The FX10 boasts several capabilities that set it apart from its predecessors. With a print chamber twice the size of the X7, the FX10 provides a more spacious printing environment while also ensuring rapid and efficient printing processes.

- Heated chamber allowing more stable printing of Onyx at higher temperatures

- High-speed printing of composites with Turbo Mode

- Modular Print System

- Compatible with Onyx and Continuous Carbon Fiber

Markforged FX20 3D Printer

The Markforged FX20 combines great dimensions and processing capacity to facilitate the creation of larger builds at immaculate speeds. Tailored for a wide range of applications, the FX20 is built to create strong, high temp parts. An intricately crafted, sensor-guided manufacturing 3D printer that achieves groundbreaking reliability and performance with a simple user experience.

- The only 3D printer compatible with Markforged’s new material Vega™. Vega™ is Markforged’s first engineered high temperature plastic.

- Continuous fiber reinforcement

- Turbo mode which allows for printed parts faster than any other Markforged machine

- Build chamber 5x the size of any other Markforged machine

- Compatible with Onyx™, Vega™, ULTEM™ 9085 Filament, and Onyx FR™