Markforged FX20 3D Printer Industrial Series

This Markforged FX20 3D printer (from Markforged's Industrial Series) contains an 84L heated build chamber, verified-flat vacuum bed with print sheets, and so many more innovative features. Pairing size and throughput, this revolutionary machine is able to create larger builds at unbelievable speeds. With a featured 7 inch touchscreen, any user has the power to control nearly every detail of the printer. In addition, the Markforged FX20 includes sensors that provide live feedback on machine performance to the user.

Process: Fused Filament Fabrication, Continuous Fiber Reinforcement

Build Volume:

Single-nozzle builds: 525 x 400 x 400 mm (20.6 x 15. x 15.7 in)

Multi-nozzle builds: 500 x 400 x 400 mm (19.7 x 15.7 x 15.7 in)

Weight: 450 kg (1000 lbs)

Machine Footprint: 1325 x 900 x 1925 mm (52.2 x 35.5 x 75.75 in)

Temperatue Control: Up to 200°C steady-state

Print System: Direct-drive print head with three nozzles (two plastic, one fiber)

Connect With a Saratech Expert Today to Get Started.

Markforged FX20 3D Printer Capabilities

The Markforged FX20 is the Biggest, Fastest, and Most Sophisticated 3D Printer Markforged Ever Built. This large format Markforged FX20 is the 3D printer features an 84L heated build chamber and massive, verified-flat vacuum bed with print sheets. The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately. FX20’s turbo mode builds parts faster than any Markforged machine, while new XL spools offer four times the material without spool changeover.

The Markforged FX20 is remarkably easy to use. It features a 7 inch touchscreen from which users can control every aspect of the printer. Automated calibration and leveling reduces operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

Massive Builds, Faster: The Markforged FX20 pairs size and throughput to make larger builds at incredible speeds, delivering the transformational benefits of The Digital Forge at a new scale.

Markforged FX20 3D Printer Features

The Markforged FX20 combines great dimensions and processing capacity to facilitate the creation of larger builds at immaculate speeds. Tailored for a wide range of applications, the FX20 is built to create strong, high temp parts. An intricately crafted, sensor-guided manufacturing 3D printer that achieves groundbreaking reliability and performance with a simple user experience.

- The only 3D printer compatible with Markforged’s new material Vega™. Vega™ is Markforged’s first engineered high temperature plastic.

- Continuous fiber reinforcement

- Turbo mode which allows for printed parts faster than any other Markforged machine

- Build chamber 5x the size of any other Markforged machine

- Compatible with Onyx™, Vega™, ULTEM™ 9085 Filament, and Onyx FR™

Plastic Compatibility

* Material not yet compatible with Markforged FX20. Support for Markforged plastic and fiber materials will be added over time, although not every combination.

VEGA™ 9085 FILAMENT

Vega™ is Markforged’s first engineered high-temperature plastic, featuring an ultra high-performance composition with carbon fiber filled PEKK for the 3D printing of essential aerospace components. By incorporating continuous fiber, Vega attains strength comparable to aluminum, making it suitable for replacing non-critical structural elements in the aerospace industry. Notably, Vega showcases a sleek black matte surface finish, ideal for production parts that require little to no post-processing.

ULTEM™ 9085 FILAMENT

Being an extremely durable thermoplastic, Ultem™ 9085 Filament is Markforged’s first high temperature printing polymer that brings 3D printing technology to the next level.

ONYX FILAMENT

Designed to combine the toughness and durability of Nylon with the dimensional stability and strength of composites, Onyx is the world's most capable 3D plastic.

ONYX FR

Fiberglass reinforced Onyx composites are as strong as metal and 20x stiffer than typical 3D printed parts. Onyx FR should be used to print parts that require high-strength, low-weight, and flame-retardant properties.

ONYX ESD*

Onyx ESD is a static-dissipative chopped carbon fiber nylon material, precision-engineered for a tight range of surface resistance. Onyx ESD meets ESD-safe requirements while offering the same industry-leading print quality of Onyx.

NYLON*

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

Continuous Fiber Compatibility

* Material not yet compatible with Markforged FX20. Support for Markforged plastic and fiber materials will be added over time, although not every combination.

CARBON FIBER

The strongest and stiffest fiber with the highest strength-to-weight ratio. Carbon fiber filament can replace aluminum at half the weight. Utilize this material when you want exceptional stiffness and minimal deflection.

*FIBERGLASS

Fiberglass is the perfect entry-level fiber for 3D printing. It's low cost and 26x more rigid than nylon. Print parts that are an order of magnitude stiffer than typical 3D printed objects and produce functional prototypes, fixtures, jigs, and much more.

*KEVLAR

As stiff as fiberglass and much more malleable, Kevlar possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. An excellent option for a wide range of applications such as end effectors, cradles, soft jaws, and end-use parts.

*HSHT FIBERGLASS

With the highest impact resistance and a flexural strength only second to carbon fiber, HSHT Fiberglass is ideal for applications requiring high heat resistance such as welding fixtures or thermoset molds.

Additive Manufacturing Savings

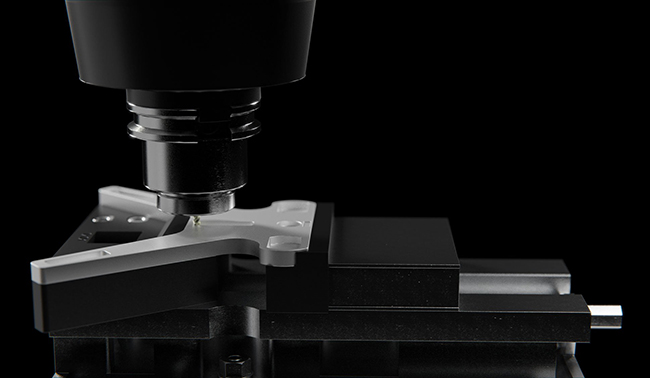

End Effectors

Keep your production line running at full speed. Reduce lead time and cost on end effectors by printing on-site same day tooling. Print new tools and functional replacements for old parts. Save time and money with carbon fiber 3D printing.

Typical Machined Cost: $ 285.61

Markforged 3D Printed Cost: $ 9.45

Savings: 97%

Soft Jaws

Use your CNC resources for only the most critical machining operations. Increase machining bandwidth by 3D printing composite-reinforced soft jaws and custom work-holding tools with the strength necessary for heavy duty machining operations.

Typical Machined Cost: $ 721.70

Markforged 3D Printed Cost: $ 116.04

Savings: 84%