Markforged 3D Printer Guide: Nylon vs Onyx

Blog Article | December 2, 2019

Markforged Nylon vs Markforged Onyx

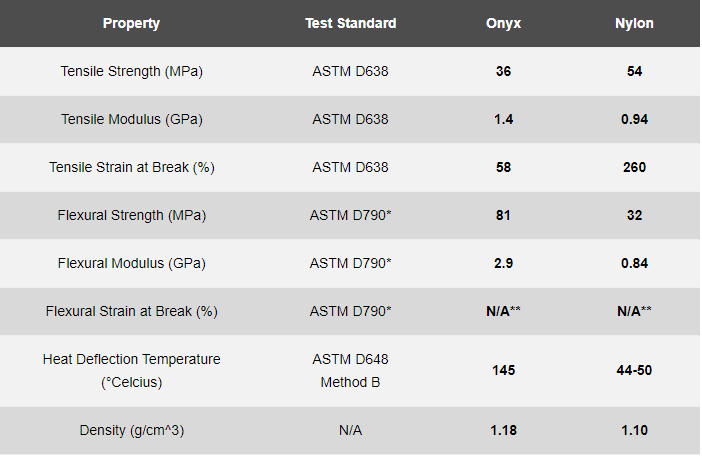

Markforged Nylon 3d Printer and Markforged Onyx are two plastics with excellent heat resistance, surface finish, and chemical resistance. Both materials can be stiffened with any of Markforged's continuous fiber options. For printing white colored parts, both Nylon and Onyx are interchangeable; however, Onyx is slightly stronger.

3D Printing Solutions

Saratech offers sales, service, and support of Markforged, and BigRep 3D printers. The breadth of 3D Printing technologies allows us to provide the right solutions according to customer requirements.

Find the Right Solution for Your Needs. Connect With a Saratech Expert Today.

Nylon

Nylon is an engineering thermoplastic that is a versatile material both with and without reinforcing fibers. Parts produced with Nylon are smooth, non-abrasive, and easily painted. Nylon can be enhanced with any continuous fiber and works best for non-marring work holding, repeated handling, and cosmetic parts.

Onyx

Markforged Onyx is an ideal material for customers who need parts that require real strength and stiffness. Onyx serves as a thermoplastic matrix for Markforged's composite parts. Use Onyx on its own, or further reinforced with embedded continuous carbon fiber, Kevlar, or fiberglass layers.

- Like all Markforged materials, parts printed using Onyx are ready for use right off the print bed.

- Onyx has a heat deflection rating of 145°C

- Parts printed in Onyx warp far less than parts printed in Nylon

Onyx is based on remarkably tough Nylon, but also provides parts with stiffness equal to or greater than any pure thermoplastic material available for professional Markforged 3d printers. Use Onyx filament for anything from tooling and fixtures to end-use parts.