Industry Updates & News From Saratech — July 2025

Blog Article | July 22, 2025

Announcements: New Resources

Saratech is excited to announce new additions to the Software and Technical Service departments! With their expertise, Manoj Gajjala and James Duncan are invaluable to our team, allowing us to offer deeper insights, faster solutions, and more specialized support in PLM systems and aerospace integration. Both Manoj and James bring advanced technical knowledge and industry experience that will streamline digital product development and improve the overall customer experience.

Manoj Gajjala | PLM Application Engineer

Manoj joins the Software department as a PLM Application Engineer. With a Master’s degree in Computer Science and professional experience in both traditional and cloud-based data environments, he brings a strong technical foundation and a drive to solve complex data challenges. His background includes designing scalable data systems, improving data quality, and contributing to cloud migration efforts that streamlined analytics and reduced processing time. We look forward to his contributions on our team!

James Duncan | Flight Deck Integration Specialist

With over 8,700 hours of flight experience, James brings valuable hands-on knowledge to our Technical Services team. A graduate of Georgia Tech in Aerospace Engineering and a former test pilot with Piper Aircraft, he will play a key role in advancing our aerospace integration projects. His dual perspective as both an engineer and experienced pilot enhances our ability to deliver high-performance, real-world aviation solutions. We’re excited to welcome James to Saratech and look forward to the contributions he’ll make in aiding our clients.

Boost Your Team's Skills - Get 3 for the Price of 2

For a limited time, when you register and pay for two students, a third attends free. Maximize value and accelerate learning with Saratech's expert-led training.

Some restrictions apply. Contact us for details.

Optimize CNC Workflows With Saratech’s ISV Kits

Take your CNC machining to the next level with Saratech’s Integrated Simulation & Verification (ISV) Kits. Fully embedded within Siemens NX, our ISV Kits combine post-processing and G-code simulation into a single streamlined workflow. Compatible with leading CNC machines and controllers, this solution reduces programming errors, improves part quality, and enhances overall machining efficiency.

Upcoming Training & Events

Boost productivity with practical training on the latest Siemens PLM software tools.

Join us at the UC Irvine 3D Printing Lab on July 24th at 10 AM for a live showcase of two of the most advanced 3D Printers on the market. Discover how companies in aerospace, automotive, and manufacturing industries are leveraging this technology to stay ahead. Don’t miss this opportunity to see the future of industrial 3D printing in action!

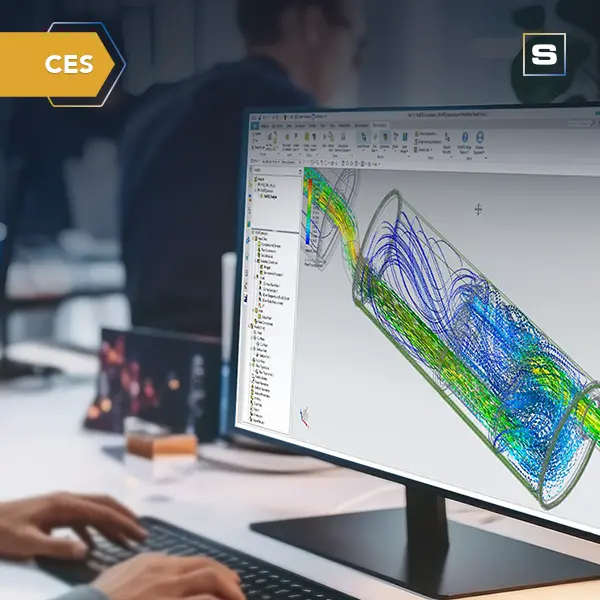

Free Training at Our Bi-Monthly CES

Register for our upcoming session Digital Thread Case Study: Deploying Teamcenter Easy Plan with Product Configurator

August 7th at 11AM PT

Keep with the latest in everything engineering by subscribing to our blog.

Designcenter NX: Scalable, Sustainable Innovation in Digital Engineering

Arc Boat Company is a Los Angeles-based startup using Siemens Xcelerator including NX, Simcenter, and Teamcenter to design and manufacture fully electric, zero-emission boats. With rapid in-house innovation, Arc has launched breakthrough vessels like the Arc Sport and is now expanding into commercial marine applications. Their mission? Deliver high-performance, sustainable marine experiences through smart software integration and bold design.

Siemens Teamcenter User Guide

Industry News

Design Copilot NX

Siemens unveiled the Designcenter NX Summer 2025 update on July 1, rolling out powerful new capabilities including a natural-language AI assistant (Design Copilot NX), integrated fluid and thermal simulation, immersive mixed-reality design/collaboration with Sony, and advanced manufacturability tools like NX Inspector and DFM Advisor. These enhancements streamline design-to-manufacture workflows, boost usability and learning, and further solidify NX’s leadership in AI-driven, scalable product engineering.

BigRep Expands With HAGE3D

BigRep has officially acquired Austrian-based HAGE3D, a move that significantly strengthens its position in the industrial additive manufacturing space. Known for its expertise in high-temperature 3D printing, HAGE3D brings decades of engineering experience and a portfolio of advanced FFF platforms to the table. This acquisition allows for a complete range of large-format printing solutions spanning low, mid, and high-temperature applications, and supports a wider variety of engineering-grade materials. With this strategic partnership, BigRep expands its global reach, adds Graz to its network of innovation hubs, and enhances its ability to serve manufacturers seeking scalable, open-platform AM solutions.

316L Stainless Steel on Markforged FX10

Markforged has officially launched 316L Stainless Steel for its FX10 industrial 3D printer, meeting years of customer demand for this highly requested material. Known for its outstanding corrosion resistance and durability in harsh environments, 316L unlocks new applications in industries such as food and beverage processing, automotive, petrochemical, medical, and marine. Following nearly 5,500 print hours of testing across eight FX10 units, the material proved highly reliable, with print success rates exceeding all targets. With 316L, customers can now manufacture strong, accurate metal parts for tooling, prototypes, spare parts, and end-use components, expanding the FX10’s value across more production environments. This launch marks a major step in strengthening FX10’s position as a go-to solution for versatile metal printing.