Finite Element Analysis (FEA) Consulting Services

Demand for Finite Element Analysis (FEA) consulting engineers and Computer-Aided Engineering (CAE) services has grown rapidly as engineering tools and computing power continue to advance. Today’s simulation technologies allow companies to more accurately predict how products will behave under real-world physical conditions—long before anything is built.

Originally rooted in aerospace, FEA is now widely used across industries including electronics, automotive, industrial machinery, medical devices, and consumer products. By enabling virtual testing and digital prototyping, FEA gives engineering teams the freedom to explore more design options, identify risks earlier, and troubleshoot performance issues without the cost and time required for physical prototypes.

Saratech’s FEA consulting services help manufacturers take a critical step in product development: performance validation before tooling and manufacturing decisions are made. Our experienced FEA engineers develop robust simulation models and translate complex results into clear, actionable insights—helping customers reduce cost, mitigate risk, and accelerate time to market.

Make Smarter Decisions with Saratech’s FEA Consulting Services

FEA Services Designed Around Your Engineering Needs

Saratech provides expert FEA consulting services tailored to your product, development stage, and performance requirements. From early design feasibility to detailed validation, our engineers develop and execute simulations that accurately predict structural, thermal, and dynamic performance. While our focus is FEA, we also leverage CAE and CFD tools when needed to provide a complete picture of product behavior. By working closely with your engineering team, we ensure models are appropriately scoped, assumptions are realistic, and results are translated into actionable recommendations—helping you make confident, data-driven decisions and reduce risk before committing to physical testing or manufacturing.

The Value of FEA Consulting With Saratech

FEA delivers the most value when it provides actionable insights that drive better engineering and business decisions. Saratech’s experienced consultants use simulation to reduce the need for costly physical prototypes, lower development risk, and improve product performance. By translating results into clear guidance, our team helps engineering teams understand not just what the data shows, but what actions to take next. With the right assumptions, tools, and expertise, Saratech navigates the complexity of FEA to tackle challenging design problems, validate components, and evaluate performance across a wide range of operating conditions—helping teams make faster, more confident product development decisions.

Reduce Development Risk

Reduce development risk by identifying structural, thermal, or dynamic issues early in the design cycle

Lower Costs

Lower costs by minimizing physical prototyping, redesign, and late-stage changes

Improve Product Performance & Reliability

Improve product performance and reliability through data-driven design decisions

Accelerate Time to Market

Accelerate time to market by validating designs digitally before committing to tooling

Focus Internal Resources

Focus internal resources while leveraging experienced FEA engineers on demand

Saratech’s FEA Capabilities

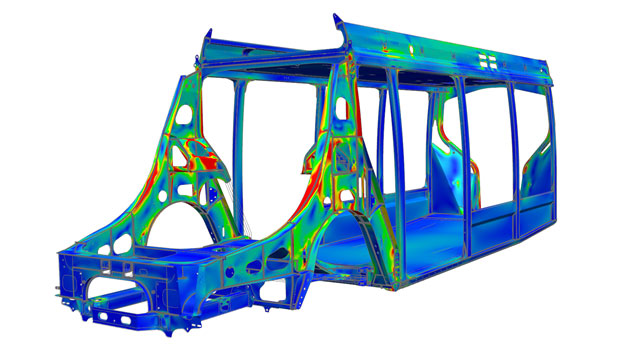

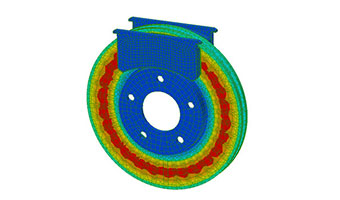

Structural Analysis

Structural Analysis tests the stress placed on a component and evaluates the potential for deformation or fracture under varying operational conditions. This allows designers and engineers to determine the safety of the component when withstanding forces acting against it.

Multibody Dynamics

Multibody dynamics predicts motions and displacement by calculating loads on various parts of a system. This helps determine what would happen if a part works to potentially break or if a mechanism will work as originally designed.

Dynamic and Vibrational Analysis

Dynamic and vibrational analysis determines the shape of structures at different resonant frequencies by computing the resonant frequencies of a structure. This helps product engineers better predict the behavior of a system, allowing product engineers to go beyond traditional static analysis.

Thermal Analysis

Thermal Analysis helps product engineers who need to reduce the risk of failure to thermal stress. Thermal analysis provides an understanding of heat loads and temperature destruction by using the transfer of heat in a component through convection, conduction and radiation.

Industries We Serve

Aerospace & Defense | Medical Devices & Pharmaceuticals | Automotive & Transportation | Energy & Utilities | Industrial Machinery & Heavy Equipment | Electronics & Semiconductor | Marine | Consumer Products

Why Choose Saratech for FEA & CAE Services

Engineering-Led Consulting

Saratech is an engineering services organization first. Our FEA consultants bring hands-on experience developing, validating, and interpreting simulation models across a wide range of industries and applications.

Practical, Decision-Focused Results

We don’t deliver raw simulation output alone. Our focus is on providing clear conclusions and engineering recommendations that help teams move forward with confidence.

Full Spectrum Service

Saratech offers the entire spectrum of FEA and CAE consulting services, from conceptual design to detailed analysis to testing and even manufacturing. We coordinate all aspects of the project, freeing our customers to focus on product development.

Scalable Support

Saratech supports customers through project-based analysis, engineering support, and extended team collaboration—allowing you to engage FEA expertise at the level and duration your project requires.

Time & Cost Effective

Our team is very schedule-driven, ensuring that every project is completed on time and within budget. Our engineers have extensive expertise in FEA and CAE tools, enabling us to identify potential problems and deliver actionable information.

Saratech Engineering Services Case Studies

AEROSPACE, DEFENSE, SPACE & INDUSTRIAL

Product Development Resources

Gain critical insight into what to look for in your service provider and ensure you ask the right questions to guarantee the best match for your company.

Learn how to overcome the top simulation issues experienced by companies.

Frequently Asked Questions

What types of analysis can be performed using FEA?

FEA can simulate a wide range of conditions, including structural stress and strain, thermal performance, vibration and dynamic behavior, fatigue and fracture, and material-specific responses. At Saratech, we also integrate CAE tools and, when needed, CFD simulations to provide a complete view of product performance.

How long does an FEA project take?

Project timelines depend on factors such as design complexity, analysis type, and development stage. Saratech works closely with each customer to define the project scope, prioritize key engineering questions, and establish a schedule that ensures timely delivery of actionable results without compromising quality.

Can FEA be used on legacy designs?

Yes. FEA is highly effective for evaluating existing or legacy products. Saratech engineers can develop simulation models from available geometry and data to identify potential weaknesses, assess performance under new operating conditions, or support redesigns—without requiring a complete rebuild from scratch.

How accurate are FEA results?

FEA accuracy depends on model fidelity, material data, and boundary conditions. Saratech’s experienced engineers ensure simulations use the right assumptions, validated inputs, and appropriate modeling techniques to produce reliable, actionable insights for design and manufacturing decisions.

What data or inputs are needed to start an FEA project?

Typical inputs include 3D CAD geometry, material properties, boundary and load conditions, and any relevant operational requirements. Saratech works with your team to ensure the necessary information is captured and any assumptions are validated for accurate, actionable results.

Can FEA help optimize my product for performance and cost?

Absolutely. FEA allows engineers to explore multiple design options virtually, identify stress concentrations, reduce over-engineering, and optimize material usage. Saratech leverages these insights to help customers improve performance while minimizing development cost and risk.

Engineering Informative Articles

Stay informed on industry leading Engineering Process and Data Management Solutions Software, Engineering and Consulting Services, and Manufacturing Hardware.