3D Printing Solutions

Saratech offers sales, service, and support of Markforged, and BigRep 3D printers. The breadth of 3D Printing technologies allows us to provide the right solutions according to customer requirements.

Find the Right Solution for Your Needs. Connect With a Saratech Expert Today.

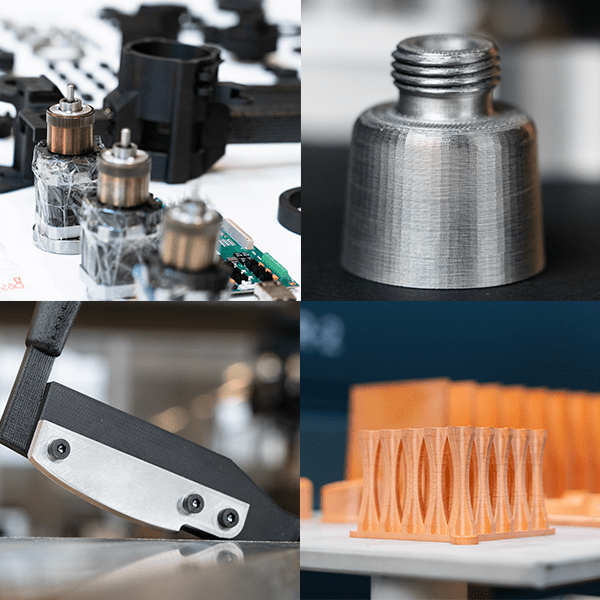

Markforged 3D Printing Solutions

Markforged products transcend the realm of 3D printing prototypes and trinkets. Using unique technology to print amazing carbon fiber parts that can be reinforced for metal-strength, we break down the barriers between idea and reality for every designer, engineer and manufacturer.

Learn More About Markforged 3D Printing Capabilities & Explore All Markforged 3D Printers.

BigRep Large Format 3D Printing Solutions

BigRep 3D printers were created for a range of applications: from industrial rapid prototyping to ready-to-go design products. They provide you an affordable and easy-to-use technology for large objects and ideas.

Explore BigRep 3D Printers & Solutions.