Markforged X7 3D Printer: Stronger Than Machined Aluminum

Designed from the ground up to survive the production floor environment, the Markforged X7 3D printer (from Markforged's Industrial Series) can print parts stronger than machined aluminum for a fraction of the cost. Produce industrial-grade manufacturing jigs, ajaws, tools, fixtures, and end-use parts with breakthrough quality and precision. The Markforged X7 3D printer delivers unparalleled surface finish, build size, and reliability.

Connect with a Saratech expert today to get started.

The Markforged X7 3D Printer Just Got Faster!

Introducing Turbo Print for the Gen 2 Markforged X7 3D printer. With Turbo Print, you can print Onyx parts at twice the speed of a standard Markforged X7 3D printer. The quicker you can produce parts, the faster you are achieving ROI.

Users can expect:

- Faster lead times

- Become more agile in manufacturing operations

- Reduce development time and line downtime

Start accepting more print jobs and achieve twice the amount of production! Print at 250 um, and of course, Turbo printed parts will maintain Markforged's unbeatable surface finish.

Markforged Metal X7 3D Printer Features

The X7 delivers the strength you need for tooling and functional parts. Cut costs and eliminate effort with this industrial printer designed for accuracy and built to survive the production floor environment. The standard options available for the X3 and X5 are also available for the X7. Cloud-connected software and a 4.3” touchscreen come standard with every Markforged printer. With automatic version control, real-time fleet management, and cloud-based collaboration, Markforged's own 3D printing software, Eiger, is one of the best software platforms of its type on the market. Additionally, laser bed leveling is supplied, allowing precision to just 1 micron in the z-axis, and an advanced sensor suite provides unparalleled reliability. Add to that an ultra-flat gantry system and a machined aluminum stage with kinematic bed coupling, the incredibly versatile X7 delivers unmatched performance. With the Gen 2 X7's Turbo Print mode, you can print Onyx parts at twice the speed of a standard Markforged X7. The quicker you can produce parts, the faster you are achieving ROI.

Markforged Metal X7 3D Printer Specifications

- Printing Process: Continuous Fiber Reinforcement (CFR)

- Z Layer Resolution: 50 μm - 250 μm

- Build Volume: 330 x 270 x 200 mm (13 x 10.6 x 7.9 in)

- Weight: 48 kg (106 lbs)

- Machine Footprint: 584 x 483 x 914 mm (23 x 19 x 36 in)

- Print Bed: Kinematic coupling — flat to within 80 μm

- Laser: In-process inspection, active print calibration, bed leveling

- Extrusion System: Second-generation extruder, out-of-plastic and out-of-fiber detection

Plastic Compatibility

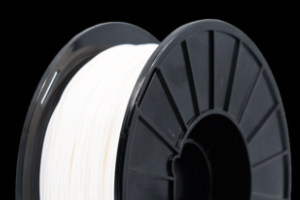

Onyx®

Designed to combine the toughness and durability of Nylon with the dimensional stability and strength of composites, Onyx is the world's most capable 3D plastic.

Onyx FR™

Fiberglass reinforced Onyx composites are as strong as metal and 20x stiffer than typical 3D printed parts. Onyx FR should be used to print parts that require high-strength, low-weight, and flame-retardant properties.

Onyx ESD™

Onyx ESD is a static-dissipative chopped carbon fiber nylon material, precision-engineered for a tight range of surface resistance. Onyx ESD meets ESD-safe requirements while offering the same industry-leading print quality of Onyx.

Nylon*

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

Precise PLA

Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable.

Smooth TPU 95A

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

Continuous Fiber Compatibility

Carbon Fiber

The strongest and stiffest fiber with the highest strength-to-weight ratio. Carbon fiber filament can replace aluminum at half the weight. Utilize this material when you want exceptional stiffness and minimal deflection.

Carbon Fiber FR

Carbon Fiber FR is a flame-retardant version of Markforged’s high-strength Continuous Carbon Fiber. When reinforcing a base like Onyx FR, it creates parts as strong as 6061-T6 aluminum. This material is extremely stiff and strong, allowing precise reinforcement of various geometries with just a few clicks.

Fiberglass

Fiberglass is the perfect entry-level fiber for 3D printing. It's low cost and 26x more rigid than nylon. Print parts that are an order of magnitude stiffer than typical 3D printed objects and produce functional prototypes, fixtures, jigs, and much more.

Aramid Fiber (Kevlar®)

As stiff as fiberglass and much more malleable, Kevlar possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. An excellent option for a wide range of applications such as end effectors, cradles, soft jaws, and end-use parts.

HSHT Fiberglass

With the highest impact resistance and a flexural strength only second to carbon fiber, HSHT Fiberglass is ideal for applications requiring high heat resistance such as welding fixtures or thermoset molds.

Maximize Your X7 Performance — Work with Saratech Experts Today

Saratech helps you get the most from your Markforged X7 by providing hands-on guidance for material selection, print optimization, and application-specific workflow integration. Our team can assist with functional part design, tooling assessments, and continuous fiber reinforcement strategies — ensuring your prints meet strength, durability, and precision requirements. With expert support for onboarding, troubleshooting, and workflow best practices, Saratech helps you reduce lead times, improve ROI, and confidently scale production with your X7.

Why Engineers Choose the Markforged X7

Engineers rely on the X7 for its unmatched combination of strength, precision, and reliability. With continuous fiber reinforcement and industrial-grade materials, the X7 delivers functional parts and tooling that outperform traditional methods — helping engineers meet demanding production requirements faster and with confidence.

Manufacturing Applications for the Markforged X7

From durable jigs and fixtures to end-use components, the X7 enables manufacturers to streamline operations and reduce lead times. Its versatile material options and industrial-grade performance make it ideal for aerospace, automotive, electronics, and general manufacturing applications where speed, strength, and accuracy matter.

How Continuous Fiber Reinforcement Replaces Machined Aluminum

Properly reinforced X7 parts can rival the strength and stiffness of machined aluminum for many tooling, fixture, and functional applications, often at lower cost and weight. By reinforcing high-performance polymers with carbon fiber, fiberglass, or Kevlar®, you can replace metal tooling and functional parts without sacrificing performance.

Precision & Repeatability with Laser Calibration

The X7’s in-process laser inspection and bed leveling ensure parts are printed with micron-level accuracy every time. This precision guarantees consistent quality, reduces scrap, and minimizes post-processing — giving customers confidence that every part meets specifications.

Scalable Production with Eiger Cloud Software

Markforged’s Eiger software makes it easy to manage single printers or fleets. Cloud connectivity allows version control, real-time monitoring, and collaboration across teams, enabling businesses to scale production without adding complexity or losing oversight.

What’s Included with the Markforged X7

The X7 comes complete with industrial-grade hardware, a 4.3” touchscreen, Eiger cloud software, automatic version control, laser bed leveling, and an advanced sensor suite. Everything you need to start producing high-quality, functional parts right out of the box.

Selecting the Right Material for Your Application

With a broad portfolio of Onyx, high-strength composites, thermoplastics, and continuous fibers, the X7 lets you choose the perfect material for your part’s strength, heat resistance, or flexibility requirements. Matching the right material to your application maximizes performance, reliability, and ROI.

X7 vs Traditional Machining: Speed, Strength, & Savings

The X7 can produce parts faster, lighter, and often more cost-effectively than traditional machining for tooling, fixtures, and functional components designed with fiber reinforcement in mind.