What is a Digital Twin in Manufacturing?

Blog Article | October 24, 2025

Author: Madison Rye | Vice President of PLM & Application Engineering at Saratech

- 23 years of global experience in simulation and product lifecycle management in automotive, industrial machinery, medical devices, and aerospace

- Passion for process improvement and helping customers prove the value of digital transformation

- 3 years as Director or North American Channel at Siemens

- 15 years as Teamcenter services and application engineer at a Siemens partner and then at Siemens

- 5 years in service engineering and then design and development on M11 series engine at Cummins

- BS and MS in Mechanical Engineering from The Ohio State University

The Digital Twin Defined in Manufacturing

A digital twin is the virtual representation of a physical system or part—complete with all the data associated with it, including CAD models, performance calculations, jigs and fixtures, tooling, manufacturing work instructions, service manuals, and more. It encompasses mechanical, electrical, and software domains—essentially, everything that defines the product.

A digital twin mirrors how a product behaves and performs throughout its lifecycle. It enables the seamless flow of data to the right people at the right time, allowing for informed, data-driven decisions based on a complete and accurate picture.

In manufacturing, the digital twin connects data created across disciplines into one intelligent model. It serves as a foundational element of advanced product lifecycle management (PLM), linking design, engineering, manufacturing, and service into a continuous digital thread.

Why Digital Twins Matter in Modern Manufacturing

Digital twins are transforming how manufacturers design, build, and support products by:

- Accelerating innovation cycles while reducing costly risks.

- Creating a closed-loop feedback system between design, engineering, manufacturing, and service.

- Supporting decision-making with both real-time operational data and validated simulations.

This integration shortens development timelines, improves first-time quality, and ensures products are production-ready before hitting the factory floor.

Understanding the Product Lifecycle as a Continuous Loop

Because the digital twin encompasses all product data, it’s critical that this information flows through the product lifecycle quickly and accurately—without requiring someone to manually move data from one system to another. The seamless flow of the digital twin along the digital threads is where manufacturers gain the real benefits.

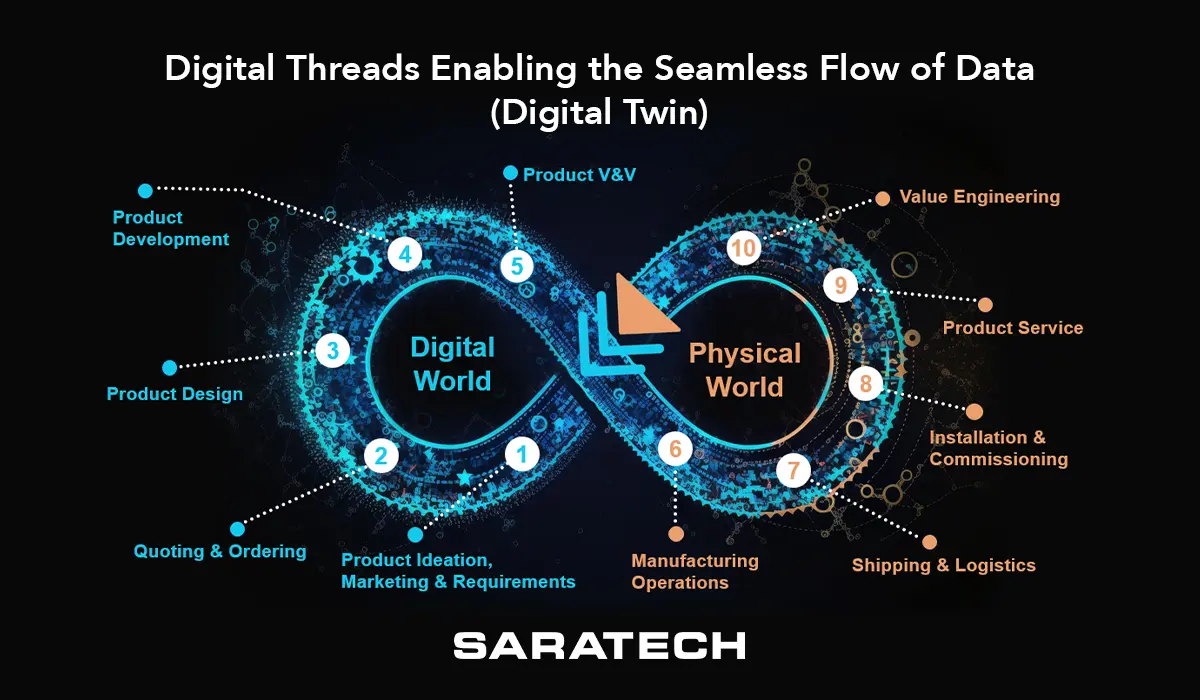

The below illustrates this continuous product lifecycle:

Every program begins with a set of requirements, a target cost, and a target schedule. It then progresses through quoting and ordering, product design and development, and testing and analysis. From there, it moves into manufacturing, shipping and logistics, and installation and commissioning (if applicable). Finally, it enters service, where all insights feed back into engineering for continuous improvement.

At every stage, the digital twin evolves with new data, creating a comprehensive view of both the virtual and physical product.

The digital thread ensures this data moves seamlessly across the entire product lifecycle. Each thread represents a specific use case—such as connecting design to manufacturing or engineering to service—and guarantees that the right data reaches the right people at the right time.

When data flows automatically through connected systems like NX, Teamcenter, and Simcenter, organizations gain measurable benefits: improved speed, accuracy, and collaboration.

When the chain is broken—such as manually transferring a BOM from engineering to ERP or exporting NX CAD files to Mastercam—it introduces risk, slows production, and creates costly rework. Seamless data flow is where the true value of the digital twin emerges.

From dBOM to eBOM to mBOM: Connecting Engineering & Manufacturing

One of the most powerful applications of a digital twin is bridging engineering intent with manufacturing execution through connected BOMs:

- dBOM (Design BOM): Generated from CAD tools like NX CAD and Solid Edge, capturing engineering design intent.

- eBOM (Engineering BOM): Refined and validated in Teamcenter, ensuring product structures are correct and configurations are approved and includes all mechanical, electrical and software components together. This can also include product options and variants for configure to order products.

- mBOM (Manufacturing BOM): Tailored for specific plants and synchronized with ERP and MES systems for production and includes consumables and raw materials

With Siemens tools such as Teamcenter BOM Management, Product Configurator, Classification, and Configuration Contexts, companies gain traceability, fewer late-stage errors, and smoother design-to-manufacturing transitions.

Digital Twins & the Bill of Process (BOP)

The Bill of Process (BOP) defines the steps and resources required to manufacture a product and connects directly with the mBOM. Digital twins enable manufacturers to:

- Validate process planning and manufacturing sequences.

- Run simulations and verifications using tools such as Tecnomatix for manufacturing processes, fully integrated with Teamcenter.

- Support virtual commissioning, ergonomic analysis, and line balancing before physical implementation.

- When change happens, the change can be passed through the design BOM to the engineering BOM to the Manufacturing BOM and BOP in an automated fashion.

This reduces costly surprises during production ramp-up and ensures manufacturing processes are safe, efficient, and optimized.

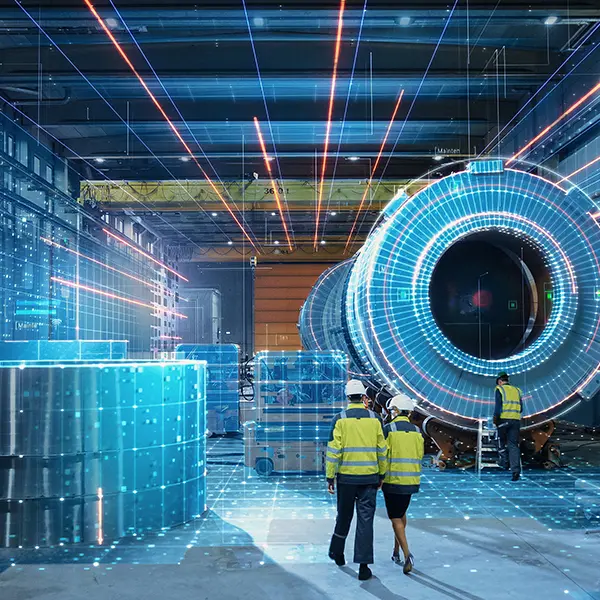

How Digital Twins Support Smart Manufacturing with Siemens

A closed-loop digital twin connects engineering, simulation, and the shop floor in real time:

- Process & Plant Simulation: Tecnomatix models production sequences, material flow, workstation layout, and cycle times to validate and optimize plant layout before physical implementation.

- Feedback & Optimization: IoT connectivity through MindSphere or other platforms provides real-world performance insights.

- Change Management: BOMs, schedules, and process plans remain synchronized for impact analysis.

This integration ensures faster decision-making, better collaboration, and adaptive manufacturing processes.

Key Benefits of Digital Twins for Manufacturers

Manufacturers adopting digital twins gain measurable advantages, including:

- Higher first-time quality with fewer reworks.

- Improved collaboration across distributed teams.

- Smarter resource planning and reduced risk exposure.

- Predictive maintenance and minimized downtime.

- Faster time-to-market through virtual validation.

Applications of Digital Twin Technology in Discrete Manufacturing

Product Configuration & Customization

Support CTO and hybrid ETO/CTO strategies with Teamcenter Product Configurator and Color Explosion visualization.

Manufacturing Process Planning

Validate line layouts and optimize production flows with BOP and mBOM synchronization.

Ergonomics & Safety Simulation

Human-centric process validation with Tecnomatix Process Simulate.

Commissioning & Plant Simulation

Achieve virtual commissioning and production readiness without costly delays.

Maintenance & Lifecycle Monitoring

IoT integration enables condition-based and predictive maintenance strategies.

Getting Started with a Digital Twin Strategy

1

Define Goals & Scope

Decide what needs to be simulated or monitored.

2

Leverage CAD & PLM Investments

Use NX, Simcenter, and Teamcenter as your foundation.

3

Align BOMs Across Departments

Connect dBOM, eBOM, and mBOM for consistency.

4

Integrate IoT & Real-Time Data

Enable data flow from sensors, MES, and ERP.

5

Pilot & Scale

Begin with one high-impact use case, then expand across the enterprise.

Ready to Put the Digital Twin to Work in Your Manufacturing? Partner with Saratech to Enable Seamless Digital Transformation

At Saratech, we help manufacturers accelerate their digital transformation by connecting and streamlining the flow of digital twin data across the entire product lifecycle. Our experts guide you in unifying design, engineering, and manufacturing systems, ensuring your teams have the right information at the right time to make smarter, faster, data-driven decisions.

Whether you’re starting with BOM alignment, process simulation, or full closed-loop integration, Saratech will support you at every step. Contact our experts today to begin building your connected digital twin strategy.

Digital Twin FAQs

What Siemens tools help create a digital twin?

NX, Teamcenter, Simcenter, Process Simulate, and MindSphere.

How does a digital twin differ from simulation?

Simulation tests scenarios; a digital twin combines simulation + live data for continuous improvement.

Can I use digital twins for both products and manufacturing lines?

Yes—digital twins apply to products, processes, and production systems.

What’s the link between a digital twin and a BOM?

The digital twin relies on connected BOMs (dBOM, eBOM, mBOM) for accuracy and traceability.

How do I maintain a digital twin over time?

By syncing with real-world data sources (IoT, MES, ERP) and updating simulations as designs evolve.

Looking Ahead – Trends in Digital Twin for Manufacturing

1

AI/ML-powered predictive twins for performance forecasting.

2

Federated twins connecting global operations.

3

Sustainability modeling for carbon and energy optimization.

4

Cloud scalability through Teamcenter X.

Conclusion

The digital twin is no longer optional—it’s a key competitive advantage. Paired with the digital thread, it ensures data flows seamlessly across the entire lifecycle—from design to production to service—without manual transfers or loss of traceability.

Manufacturers leveraging NX, Tecnomatix, and Teamcenter are already achieving next-level performance, speed, and efficiency.