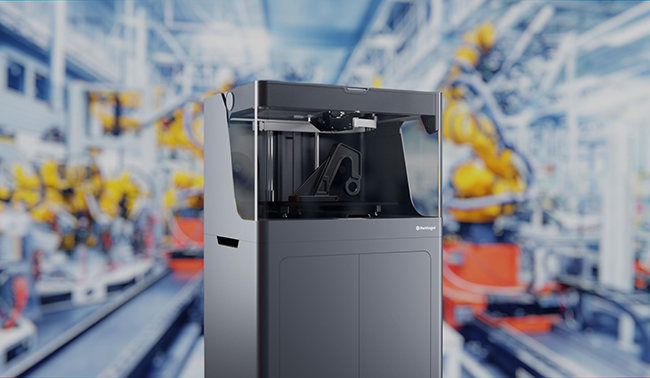

Markforged 3D Printer Guide: Industrial Series

X3, X5, X7 3D Printer Guide

Interested in Markforged's Industrial Series, but can't decide which printer is right for you? We have a guide that can help. Discover the diverse capabilities and groundbreaking attributes of the X3, X5, and X7 with this comprehensive printer guide! Topics to be covered include, build volumes, print materials, software features, and much more. Explore the additive manufacturing possibilities each printer can help you achieve and unlock the door to optimizing your production cycle today.

Speed Up Your Product Development With 3D Printing Services From Saratech

Get Started With a 3D Print Quote

X3 3D Printer

X3 Capabilities

As one of the most cost-efficient ways to produce quality engineering-grade plastic parts, the X3 is perfect for production lines. The Markforged X3 has been engineered from the ground up to offer the speed, consistency, and repeatability needed for demanding manufacturing and engineering environments. The X3 prints Onyx, a nylon and chopped carbon fiber hybrid material that's 20 percent stronger and 40 percent stiffer than ABS. With Onyx, you can 3D print jigs, jaws, tools, and fixtures with the abrasion resistance of nylon and the strength of carbon fiber.

X3 Includes

- Base Materials: Onyx, Onyx ESD, Onyx FR, Nylon, Precise PLA, Smooth TPU 95A

- Eiger Software

- (3) FFF Quick-Change Nozzle

- (1) True Bed Build Plate

- Laser Assisted Calibration

- 50 Micron Resolution

- Material Scale

X3 Features

With a build volume of 330 x 270 x 200mm and a weight of 46kg, the X3 is an industrial printer that gets the job done. Cloud-connected software and a 4.3” touchscreen come standard with every Markforged printer. With automatic version control, real-time fleet management, and cloud-based collaboration, Markforged 3D printing software, Eiger, is one of the best software platforms of its type on the market. Additionally, a built-in laser micrometer automatically scans the print bed with 1µm accuracy to generate a contour map of its surface. By calibrating its measurements with extrusion readings to perfectly set nozzle height and active topography adjustment, the X3 ensures your prints come out exactly how you want them.

X5 3D Printer

X5 Capabilities

Power your production cycle with the X5. The X5 delivers the capability to replace costly and time-consuming machining processes in a low-cost manner. The difference between the two industrial printers is with the print materials they are capable of using. While the X3 can only print Onyx, the X5 can additionally print with fiberglass. If your parts require exceptional durability, then fiberglass is the perfect material for you. Fiberglass creates parts 26 times stiffer than nylon and 11 times more rigid than ABS. As an ideal entry-level 3D printing material, fiberglass is a low-cost option that can surpass strength levels of 6061 aluminum.

X5 Includes

- Base Materials: Onyx, Onyx ESD, Onyx FR, Nylon White, P-PLA

- Fibers Available: Fiberglass

- Eiger Software

- (3) CFF Quick Change Nozzle

- (3) FFF Quick Change Nozzle

- (1) True Bed Build Plate

- Laser Assisted Calibration

- 50 Micron Resolution

- Material Scale

X5 Features

The standard options available for the X3 are also available for the X5. With the same build volume as the X3 of 330 x 270 x 200mm, the X5 is perfect for a production floor environment. Cloud-connected software and a 4.3” touchscreen come standard with every Markforged printer. With automatic version control, real-time fleet management, and cloud-based collaboration, Markforged's own 3D printing software, Eiger, is one of the best software platforms of its type on the market. Additionally, laser bed leveling is supplied, allowing precision to just 1 micron in the z axis, and an advanced sensor suite provides unparalleled reliability. Add to that an ultra-flat gantry system and a machined aluminum stage with kinematic bed coupling, the X5 nails the sweet spot of strength and affordability.

X7 3D Printer

X7 Capabilities

With the same all-aluminum unibody construction with a build volume of 330 x 270 x 200mm, the X7 appears to be not unlike the X3 or X5; however, the difference is in the print materials. The X7 offers users the ability to print not only with Onyx and fiberglass but also HSHT fiberglass (high-strength, high-temp fiberglass), carbon fiber, and Kevlar.If you have projects that require multiple types of printing materials, then Markforged's X7 is the ideal 3D printer for you. As a 3D printer capable of printing with the most diverse set of materials, the X7 is the flagship of the Industrial Series.

X7 Includes

- Base Materials: Onyx, Onyx ESD, Onyx FR, Nylon, Precise PLA, Smooth TPU 95A

- Eiger Software

- (3) CFF Quick Change Nozzle

- (3) FFF Quick Change Nozzle

- (1) True Bed Build Plate

- Laser In-Process Inspection

- Laser Assisted Calibration

- 50 Micron Resolution

- Material Scale

X7 Features

The X7 delivers the strength you need for tooling and functional parts. Cut costs and eliminate effort with this industrial printer designed for accuracy and built to survive the production floor environment. The standard options available for the X3 and X5 are also available for the X7. Cloud-connected software and a 4.3” touchscreen come standard with every Markforged printer. With automatic version control, real-time fleet management, and cloud-based collaboration, Markforged's own 3D printing software, Eiger, is one of the best software platforms of its type on the market. Additionally, laser bed leveling is supplied, allowing precision to just 1 micron in the z-axis, and an advanced sensor suite provides unparalleled reliability. Add to that an ultra-flat gantry system and a machined aluminum stage with kinematic bed coupling, the incredibly versatile X7 delivers unmatched performance. With the Gen 2 X7's Turbo Print mode, you can print Onyx parts at twice the speed of a standard Markforged X7. The quicker you can produce parts, the faster you are achieving ROI.